Industrial Ultrasonic Cleaners and Equipment

Kaijo primarily serves the needs of the industrial market and provides systems specifically designed and engineered to meet the challenging requirements of industrial cleaning applications. The systems will operate at frequencies that range from 19.5 kHz to 2 MHz and deliver high power ultrasonic energy to address the broad needs of industrial cleaning. With an extensive product line of industrial ultrasonic cleaners and equipment, Kaijo provides turnkey systems, integrated systems, individual components as well as customized systems to meet specific requirements. Kaijo has been an industry leader in developing new innovations in ultrasonic cleaning technology to respond to the needs of the industrial market. In addition Kaijo’s in-house experts and excellent customer support will help analyze cleaning processes and propose effective solutions.

Turn-key Ultrasonic Systems

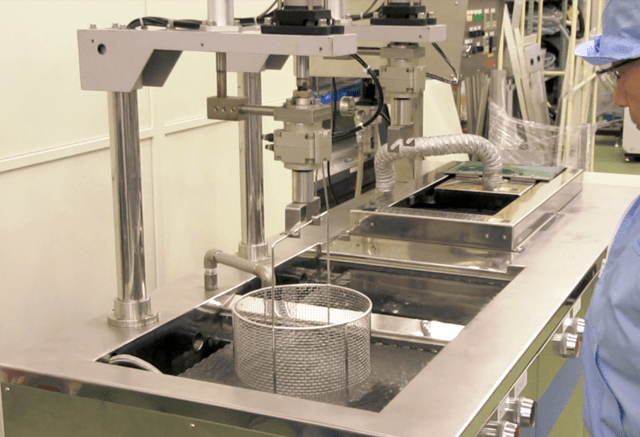

Turnkey ultrasonic cleaning systems consist of matched ultrasonic generators, transducers and cleaning tanks that are ready to use and meet specific application requirements. Kaijo has the experience to assemble turnkey solutions that meet or surpass operating expectations.

Integrated Industrial Ultrasonic Cleaning Systems

Integrated cleaning systems have the ultrasonic transducer mounted on the cleaning tank and a matched generator ready to be plugged in and start cleaning. These units can be flexible with several frequencies or frequency ranges.

Stand-alone Ultrasonic System Components

Kaijo also has a complete line of ultrasonic cleaning system components for customers who don’t need a complete system or who have existing equipment they want to use. Stand-alone generators and immersible or bolt-on transducers can be used with existing cleaning tanks and high-quality stand-alone tanks are also available.

Customized Industrial Ultrasonic Cleaners

For special cleaning requirements, a custom built ultrasonic system may be required. Kaijo can customize their systems with special frequency ranges, dual frequencies, multiple ultrasonic transducers and specialized equipment such as a water resonance system. In each case, Kaijo can analyze the unique requirements a customer has to design and build a customized industrial ultrasonic cleaning machine.

Benefits of Kaijo’s Industrial Ultrasonic Cleaners

Ultrasonic cleaners provide improved cleaning performance that can be used in many different cleaning applications. Kaijo’s industrial ultrasonic cleaners specifically provide the following benefits:

- Reduces or eliminates the use of cleaning chemicals

- Thoroughly cleans all surface areas including holes, crevices, interior surfaces or other difficult to access places on parts with complicated shapes

- Efficiently cleans a wide variety of parts and components made of different materials contaminated with different substances

- Effectively cleans contaminating substances such as grease and oil more quickly

- Provides systems that can operate cleaning solution temperatures up to 100 degrees Centigrade for applications that require heat

- Offers a complete product line of ultrasonic cleaning solutions from the lowest to the highest frequencies with cleaning power up to 1200 W

- Provides easy-to-install turnkey systems or individual components

For more information on why ultrasonic cleaners are used in industry read the following article:

7 Reasons to Clean Using the Power of Ultrasonic Cleaning Systems

Kaijo’s Services and Consulting

With its experience in the field of ultrasonic cleaning and the company’s in-house expertise, Kaijo can consult and analyze any industrial parts cleaning process. They can then propose cleaning systems or components that satisfy the requirements. Based on the objects to be cleaned and the substances to be removed, Kaijo’s team of specialists can provide effective cleaning solutions. These can include using special solvents to remove specific contaminants rapidly, special tank sizes to accommodate large parts and custom designs for difficult applications.

Drawing from their extensive list of products, Kaijo can provide equipment for new or existing projects and follow up with support and service after commissioning. Specialized products such as the Water Resonance System, or batch cleaning tools are also available. As a consultant, Kaijo can work with existing suppliers to address specialized cleaning needs where required.

Industrial Ultrasonic Cleaning Applications

Kaijo provides high performance industrial ultrasonic cleaners for many cleaning applications used in industry, but using the right combination of frequencies, power and configurations is needed for optimum results. Lower frequencies are used to remove tough grime from robust parts, such as heavy deposits on engine components. Mid-range frequencies are used for lighter contamination and can be used for all but the most delicate parts. For very light cleaning of fragile parts frequencies in the high kHz and MHz range are used.

Kaijo’s Ultrasonic Systems are used in the following industrial cleaning applications:

- Semiconductor processing equipment

- Machine parts

- Automotive Parts Cleaning

- Aluminum Engine Parts Cleaning

- Biotechnology Equipment Cleaning

- Flat panel glass processing

- Industrial Lenses

- Industrial Parts Washing

- Brass and Stainless Steel Media

- Aircraft/aerospace components

- 3D printer parts

- 3D medical printing

- Plastics manufacturing

- Electronics and printed circuit boards

- Medical device component manufacturing

- Pharmaceutical manufacturing

- Plastic Mold Cleaning

- Cleaning prior to plating or coating

- Metal Finishing

Advantages Kaijo’s Systems Provide

Using Kaijo to analyze cleaning requirements and following their recommendations for equipment has advantages over using other potential suppliers. Kaijo combines experience with in-house expertise and a full line of products that offers the following advantages:

- Company experience and expertise

- Equipment reliability and durability

- Flexibility of systems for use in various applications

- Extensive range of optional accessories

- Excellent service and support

- Low cost of ownership and a high return on investment

- Availability to work directly with existing cleaning station integrators or subsystem suppliers

As a leader in the field of industrial ultrasonic cleaners and with more than 70 years of experience, Kaijo continues to innovate and improve their technology, products and systems to meet the needs of customers. Kaijo provides free consultation to help customers decide which ultrasonic products or system they need and will also ensure that the system they get performs as expected.

Phenix III Turn Key Ultrasonic Cleaning System

This is a ready to use ultrasonic cleaning system. The complete system includes a stainless steel tank that is mounted with ultrasonic crystals and a Phenix III generator.

Ultrasonic Generators

Quava High Power Ultrasonic Generator

The Quava is our latest state-of-the-art in ultrasonic generator. It is one generator with operating frequencies from 26 kHz to 950 kHz. Special features include: Soft Start / Soft Stop, Four output modes, No field calibration needed. Ultrasonic Frequencies include 26 kHz, 38 kHz, 78 kHz, 100 kHz, 130 kHz, and 160 kHz.

Quava Multi Ultrasonic Frequency Generator

The Quava Multi includes all the features of the Quava generator, plus it allows an operator to alternate three frequencies on the fly. Advanced system technology provides efficient oscillation with uniform cleaning for many applications. Ultrasonic Frequencies include 26 kHz, 78 kHz, 130 kHz or 38 kHz, 100 kHz and 160 kHz.

Quava Mini Ultrasonic Generator

No job is too small for the Quava Mini ultrasonic system. This ready to use, table top unit is perfect for R & D use. Multiple frequencies available in one unit!

Ultrasonic Cleaning Generators: Phenix Hyper

The Phenix Hyper system is our most advanced ultrasonic cleaning generator that consists of the Phenix Hyper and a static polished stainless steel transducer. Users can run the system in standard sweep frequency output mode or the new Hyper mode. Hyper mode generates an extraordinarily uniform ultrasonic pattern that provides the most effective cleaning.

Industrial Ultrasonic Generator Phenix+

Kaijo’s new Phenix+ industrial ultrasonic generator brings ultrasonic cleaning control to new level. The highly efficient Phenix+ produces up to 1200 watts of output power while consuming no more than 7 amps. Features include touch panel controls, automatic adjustment for the cleaning environment, and uniform ultrasonic wave distribution.

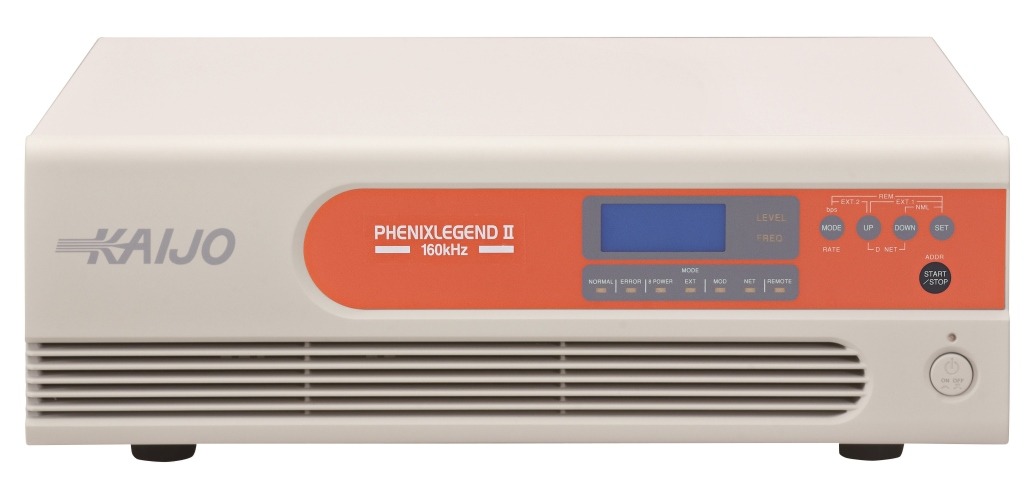

High Frequency Ultrasonic Cleaner Phenix Legend II

Kaijo’s new High Frequency Ultrasonic Cleaner the Phenix Legend II generator and transducer set is designed for precision cleaning applications. It is used for delicate or high precision applications such as the cleaning of hard disk media, flat panel glass, coated lenses, medical products, printed circuits boards or soft metals.

Ultrasonic Parts Cleaners

Phenix III Ultrasonic Parts Cleaner

High reliability at a modest price! The Phenix III Ultrasonic Cleaner offers 26 kHz or 38 kHz fixed or sweep frequency operation.

Ultrasonic Cleaning Tanks

Ultrasonic Cleaning Tanks

Choose your ultrasonic cleaning tank/bath size, frequency and power level or contact us for custom sizes and options. Choose 26 kHz or 38 kHz, and 600 or 1200 watts.

Ultrasonic Cleaning Transducers

950 kHz (1 Mhz) Ultrasonic Transducer

The 950 kHz (1 MHz) Ultrasonic transducer provides superfine cleaning of sub-micron particles on delicate parts and components including semiconductor wafers, flat panel display glass and HDD media.

38 kHz (40 kHz) Ultrasonic Transducer

The 38 kHz (40 kHz) ultrasonic transducer is available in both 600 and 1200 Watt versions. It effectively cleans stains and large contaminants from machined parts, wires, lenses, glass, ceramics, and medical devices.

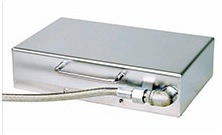

Ultrasonic Immersible Transducers

Any tank can become an ultrasonic tank with our drop-in style immersible ultrasonic transducer.

Kaijo is a global manufacturer of industrial ultrasonic cleaners and equipment and is a leading contributor to the use and innovation of ultrasonic cleaning technology. Whether you require a batch or piece-by-piece cleaning process, we can provide a solution that meets your unique cleaning requirements. If you have any questions about our products or want a free consultation on how ultrasonic products can be used for your specific application call 408 675-5575 or email info@kaijo-shibuya.com.