Ultrasonic Cleaning Systems for Industrial Cleaning Applications

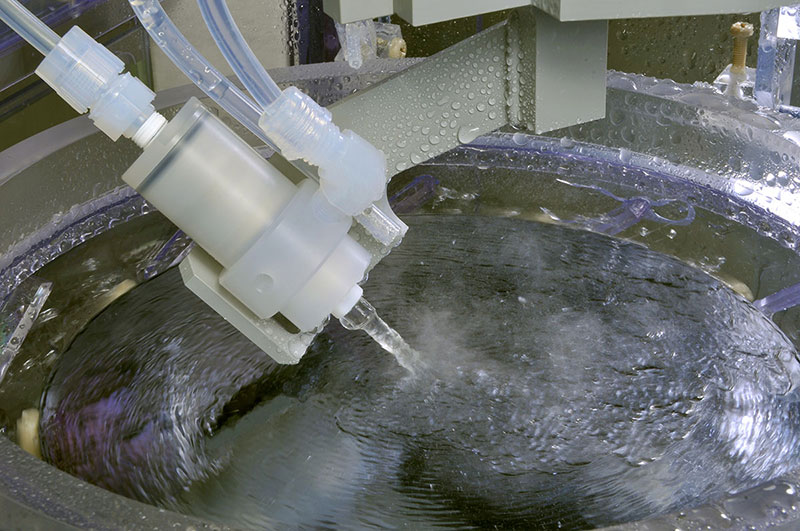

For over 70 years, Kaijo has been a global leader in developing ultrasonic cleaning technology for industrial applications. We provide a full line of ultrasonic cleaning systems, including high-performance ultrasonic cleaners and ultra-high purity semiconductor processing systems. In addition to providing ultrasonic cleaning systems, we also focus on helping our clients improve the overall performance of their industrial cleaning processes. We seek to develop and maintain long-term customer relationships by providing outstanding customer support and service. Customers who use our products will be able to reduce their operating costs with less water usage, less use of detergents and chemicals, and lower energy use.

We have a long history of offering unique state-of-the-art products and technologies. This includes the Water Resonance System (WRS), which increases the cavitation effect by over 500%. We also provide the ready-to-use Phenix III turn-key ultrasonic cleaning system comprising our most cost-effective and versatile ultrasonic generator and a static polished stainless steel ultrasonic tank. In addition, we also provide ultrasonic cleaning tanks, baths, and a new product line of high-performance ultrasonic generators.

Kaijo also promotes continuous improvement processes with ultrasonic cleaning technology and invests in research and development to bring the last technological advancements and innovations to the market. Our R&D activities are focused on introducing new technology and addressing the needs and requirements of our growing base of international customers.

Using Ultrasonic Cleaners for Your Application

Kaijo provides a complete line of industrial ultrasonic cleaners, from turn-key installations to separate components and customized equipment. Whether your needs are for batch or piece-by-piece cleaning, we can provide a solution that meets your specific application requirements. We work with clients in many industries who use our products to effectively clean parts and devices made from different materials. We’ll work with you to determine which ultrasonic cleaning system best meets your requirements. For more information or to schedule a free consultation, call 408 675-5575 or fill out our contact us form.

Featured Ultrasonic Cleaning Systems and Equipment

Phenix+ High Efficiency Ultrasonic Cleaner

The Phenix+ is our most advanced ultrasonic cleaning generator. Features include touch panel controls, automatic adjustment for the cleaning environment, and uniform ultrasonic wave distribution.

Phenix Legend II 100kHz, 130kHz or 160kHz

The Phenix Legend II high frequency ultrasonic cleaner is designed for delicate high precision cleaning applications including hard disk media, flat panel glass, and medical products.

New Phenix Hyper System

Kaijo’s new Phenix Hyper ultrasonic cleaning generator produces an extraordinarily uniform acoustic pattern to achieve complete cleanness on parts with flat surfaces or complex shapes.