Industrial Ultrasonic Cleaners and Equipment

The demands of modern manufacturing and facility management require efficiency, cost control, and consistent quality. Kaijo’s industrial ultrasonic cleaners and equipment are engineered to support these priorities by optimizing the cleaning processes, reducing operational costs, and ensuring the highest standards of component cleanliness across production batches. With a complete line of customizable systems, expert support, and a proven track record, Kaijo helps you optimize productivity and meet your goals for reliability, compliance, and process improvement.

Key Benefits of Kaijo’s Industrial Ultrasonic Cleaners

Enhanced Efficiency: Kaijo’s ultrasonic cleaners streamline processes, reduce production times, and boost throughput, helping manufacturing engineers optimize operations and cut costs.

Superior Quality: Our cleaners ensure thorough and uniform cleaning, meeting high-quality standards essential for process engineers to maintain consistent product quality.

Cost Savings: Designed for energy efficiency and low maintenance, Kaijo’s ultrasonic cleaners reduce operational costs, enabling facility managers to achieve cost-effective operations.

Customizable Solutions: Kaijo offers highly adaptable cleaners tailored to specific industrial needs, ensuring seamless integration into existing workflows for optimized performance.

Durability and Reliability: Built for demanding environments, our ultrasonic cleaners deliver robust and reliable performance, minimizing downtime and ensuring consistent facility operation.

Contact us to request a free consultation

Advanced Features of Kaijo’s Industrial Ultrasonic Cleaners

State-of-the-art Technology: Kaijo’s ultrasonic cleaners utilize cutting-edge technology to meet the rigorous demands of industrial applications. With a frequency range from 19.5 kHz to 3 MHz and advanced waveform options such as standard sweeping, pulsing, fixed frequency, FM (frequency modulation), and the Phenix Ultrasonic Hyperwave. The Water Resonance System (WRS) significantly enhances cavitation energy, promoting three-dimensional cleaning.

In-House Consulting Experts and Services

Kaijo offers comprehensive in-house consulting services to help you find the perfect ultrasonic cleaning system for your needs. Our team of experts provides personalized guidance, assessing your specific requirements and recommending tailored solutions to ensure optimal performance.

Consulting Services: We provide in-depth consulting to help you identify the most suitable ultrasonic cleaning systems for your specific operations. Our consultants work closely with you to understand your unique challenges and goals, ensuring that the chosen system meets your exact needs.

Expert Guidance: With decades of experience in ultrasonic cleaning technology, our in-house experts provide invaluable insights and recommendations. They assist in selecting the right equipment, optimizing cleaning processes, and ensuring seamless integration into your existing workflows.

Customized Solutions: We emphasize tailored solutions to address unique industrial needs. Our consulting services ensure that every aspect of your cleaning process is optimized for efficiency, quality, and cost-effectiveness.

Advantages of Kaijo’s Systems

Efficiency and Performance: Kaijo’s ultrasonic cleaning systems deliver high efficiency and superior performance, significantly improving cleaning processes and reducing production times.

Versatility: Our systems are versatile and capable of handling a wide range of cleaning tasks across various industries. This adaptability ensures optimal results for a wide range of applications.

Sustainability: Kaijo’s cleaners are designed with environmentally friendly features and energy-efficient operations, helping reduce your carbon footprint and operational costs.

Reliability: Recognized as the gold standard in ultrasonic cleaning systems, Kaijo’s products are built for reliability and long-lasting performance, minimizing downtime and maintenance needs.

Do You Need to Improve Your Industrial Cleaning Process?

Contact us to request a free consultation or quote today

Turn-Key Ultrasonic Cleaning Systems

Phenix III Turn-Key Ultrasonic Cleaning System

This is a ready-to-use ultrasonic cleaning system. The complete system includes a stainless steel tank that is mounted with ultrasonic crystals and a Phenix III generator.

Ultrasonic Generators

Quava High Power Ultrasonic Generator

The Quava is our latest state-of-the-art ultrasonic generator. It is one generator with operating frequencies from 26 kHz to 950 kHz. Special features include Soft Start / Soft Stop, four output modes, and no field calibration needed. Ultrasonic Frequencies include 26 kHz, 38 kHz, 78 kHz, 100 kHz, 130 kHz, and 160 kHz.

Quava Multi Ultrasonic Frequency Generator

The Quava Multi includes all the features of the Quava generator, plus it allows an operator to alternate three frequencies on the fly. Advanced system technology provides efficient oscillation with uniform cleaning for many applications. Ultrasonic Frequencies include 26 kHz, 78 kHz, 130 kHz or 38 kHz, 100 kHz, and 160 kHz.

Quava Mini Ultrasonic Generator

No job is too small for the Quava Mini ultrasonic system. This ready-to-use tabletop unit is perfect for R&D use. Multiple frequencies are available in one unit!

Ultrasonic Cleaning Generators: Phenix Hyper

The Phenix Hyper system is our most advanced ultrasonic cleaning generator, consisting of the Phenix Hyper and a static, polished stainless steel transducer. Users can run the system in standard sweep frequency output mode or the new Hyper mode. Hyper mode generates an exceptionally uniform ultrasonic pattern, providing the most effective cleaning.

Industrial Ultrasonic Generator Phenix+

Kaijo’s new Phenix+ industrial ultrasonic generator brings ultrasonic cleaning control to a new level. The highly efficient Phenix+ produces up to 1200 watts of output power while consuming no more than 7 amps. Features include touch panel controls, automatic adjustment for the cleaning environment, and uniform ultrasonic wave distribution.

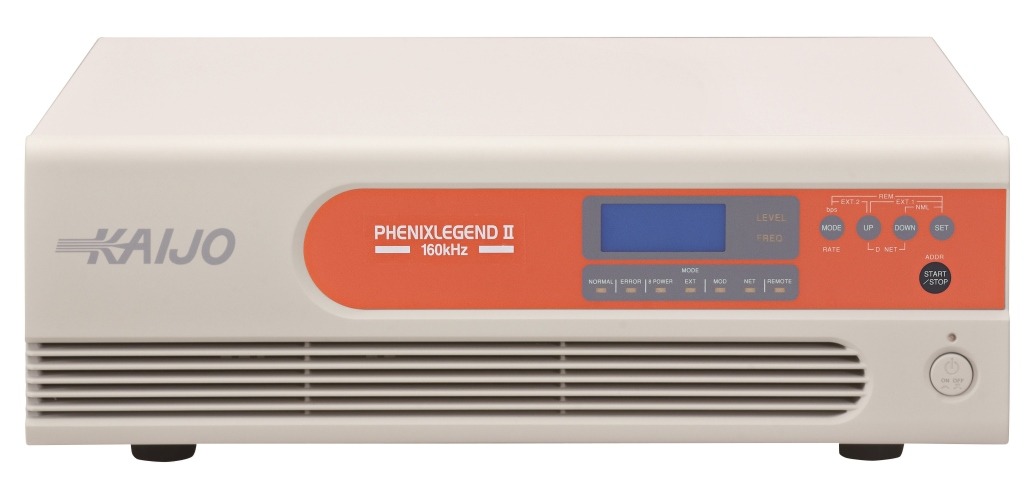

High Frequency Ultrasonic Cleaner Phenix Legend II

Kaijo’s new High Frequency Ultrasonic Cleaner, the Phenix Legend II generator and transducer set is designed for precision cleaning applications. It is used for delicate or high-precision applications such as the cleaning of hard disk media, flat panel glass, coated lenses, medical products, printed circuit boards, or soft metals.

Ultrasonic Parts Cleaners

Phenix III Ultrasonic Parts Cleaner

High reliability at a modest price! The Phenix III Ultrasonic Cleaner offers 26 kHz or 38 kHz fixed or sweep frequency operation.

Ultrasonic Cleaning Tanks

Ultrasonic Cleaning Tanks

Select your ultrasonic cleaning tank or bath size, frequency, and power level, or contact us for custom options and sizes. Choose 26 kHz or 38 kHz, and 600 or 1200 watts.

Ultrasonic Cleaning Transducers

950 kHz (1 Mhz) Ultrasonic Transducer

The 950 kHz (1 MHz) Ultrasonic transducer provides superfine cleaning of sub-micron particles on delicate parts and components, including semiconductor wafers, flat panel display glass, and HDD media.

38 kHz (40 kHz) Ultrasonic Transducer

The 38 kHz (40 kHz) ultrasonic transducer is available in both 600 and 1200-watt versions. It effectively cleans stains and large contaminants from machined parts, wires, lenses, glass, ceramics, and medical devices.

Ultrasonic Immersible Transducers

Any tank can become an ultrasonic tank with our drop-in style immersible ultrasonic transducer.

Kaijo is a global manufacturer of industrial ultrasonic cleaners and equipment, and a leading contributor to the development and innovation of ultrasonic cleaning technology. Whether you require a batch or piece-by-piece cleaning process, we can provide a solution tailored to meet your unique cleaning needs.

Are You Ready to Improve Your Industrial Cleaning Process?

Contact us for a free consultation to find the right system