Ultrasonic Liquid Flow Meter

Kaijo’s new Ultrasonic Liquid Flow Meter systems are designed to meet the diverse and demanding requirements of professionals in industrial operations. Whether you are a Process Engineer seeking to optimize efficiency, a Manufacturing Engineer aiming to reduce operational costs, or an Industrial Facility Manager focused on sustainable and compliant practices, our state-of-the-art ultrasonic flow meter is the solution you have been looking for.

Engineered with precision and reliability in mind, Kaijo’s Ultrasonic Liquid Flow Meter systems offer unparalleled accuracy and ease of use. They are an ideal choice for industries requiring meticulous flow measurement and control. With this innovative product, you can expect enhanced process efficiency, improved product quality, and significant cost savings.

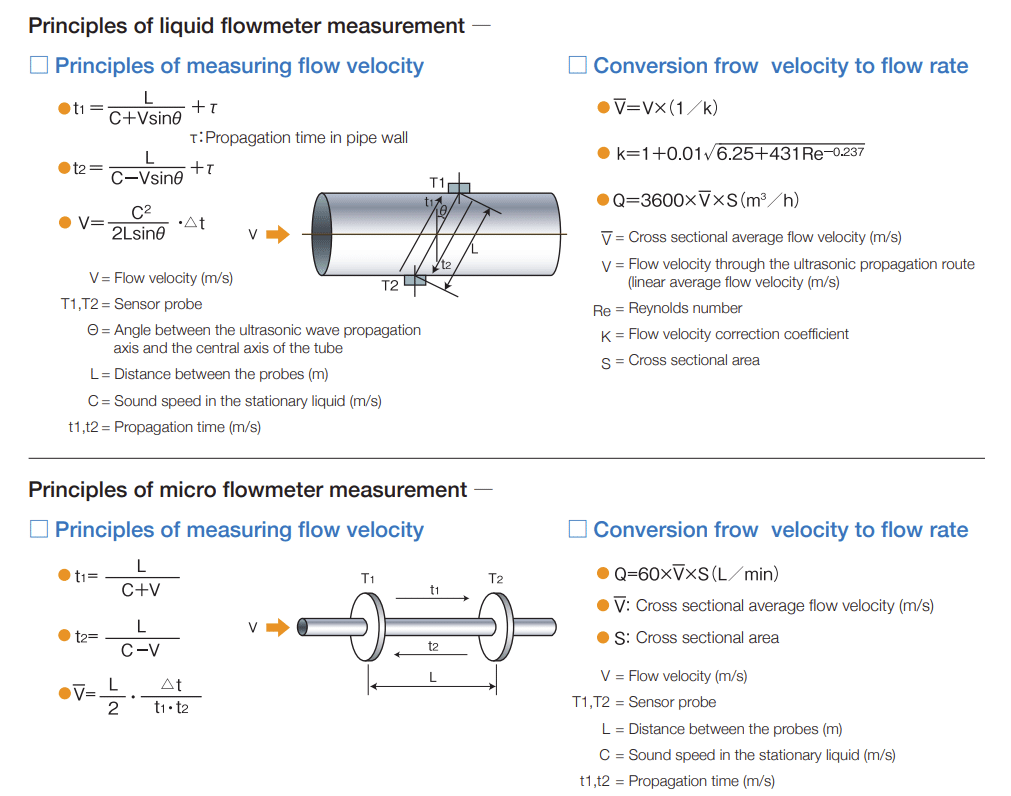

Operation:

Kaijo’s Ultrasonic Liquid Flow Meter operates using advanced ultrasonic technology. When ultrasonic waves are transmitted through a liquid flowing inside a pipeline, the propagation velocity varies according to the velocity of the flowing liquid. Utilizing this principle, the flow meter measures the velocity of the liquid flowing inside a pipeline and converts it into a flow rate, which is output as an electrical signal. This allows for the precise measurement of liquid flow without making physical contact with the fluid. This non-invasive approach ensures accurate readings while preserving the integrity of the liquid being measured. It’s particularly beneficial when the fluid cannot be contaminated, or traditional metering methods are impractical. This technology is ideal for a wide range of industrial applications due to its reliability, precision, and ease of integration into existing systems.

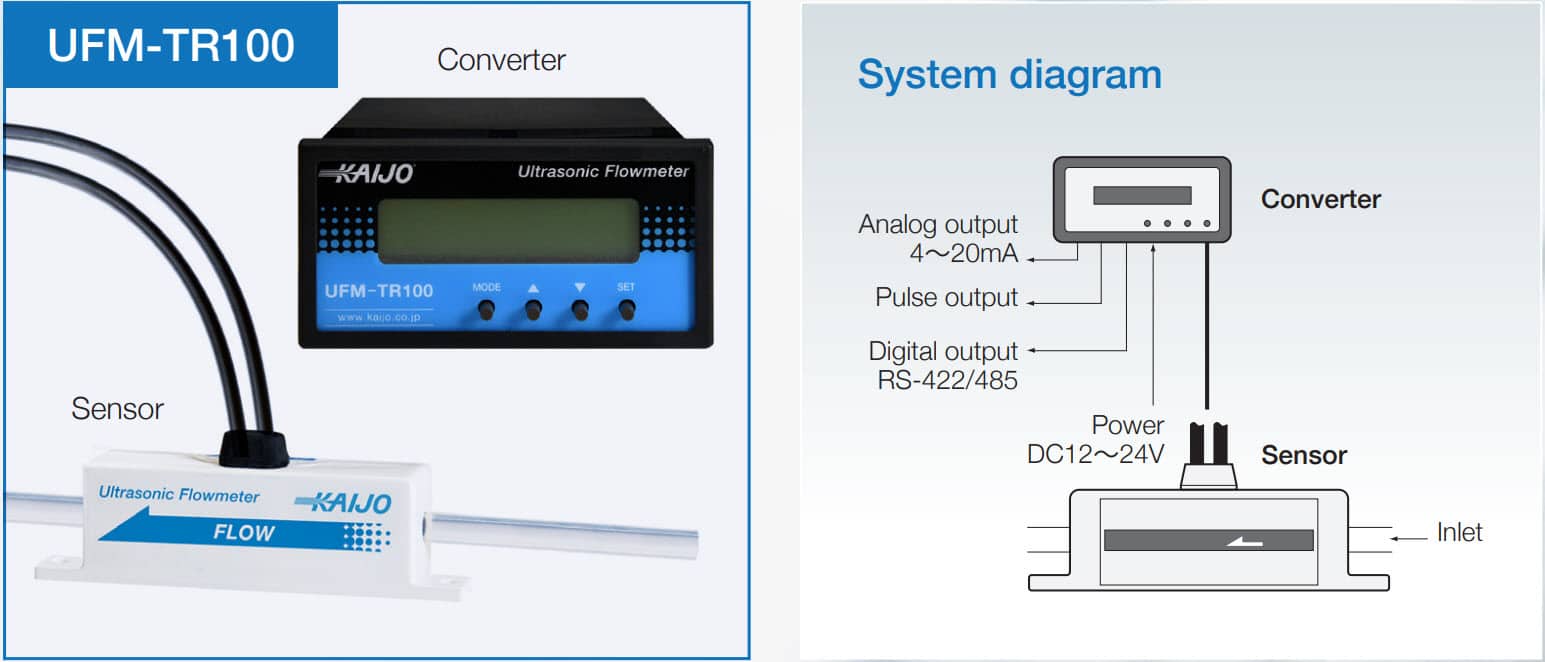

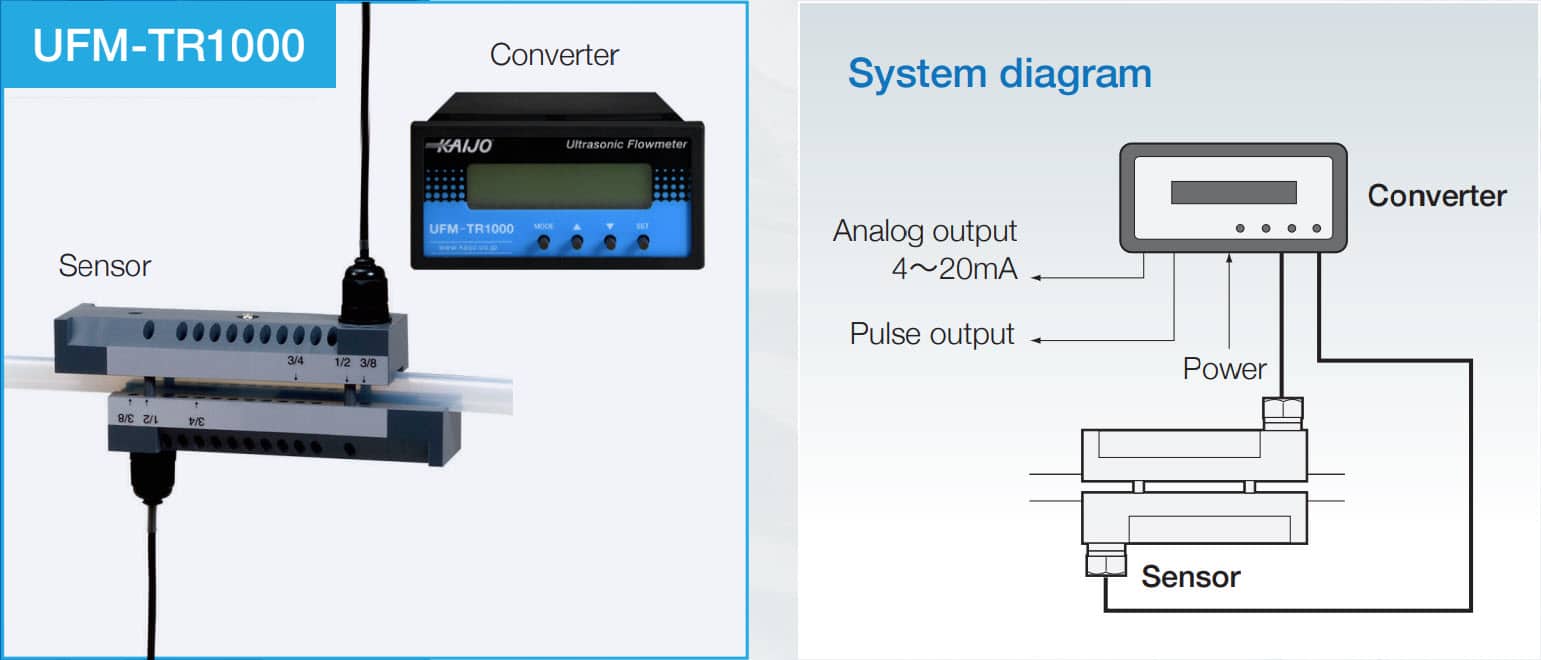

Kaijo’s ultrasonic flow meter systems are available in three configurations. The UFM-TR100 flow meter converter has a display and uses a digital cross-correction measurement method with a semi-clamp on the sensor. Another option is the UFMe-TR100 embedded flow meter converter that also uses a digital cross-correction measurement method with a semi-clamp on the sensor. The UFM-TR1000 flow meter converter has a display and uses an ultrasonic transit time measurement method with a clamp-on sensor.

Ultrasonic Liquid Flow Meter UFM-TR100 System

Features of the UFM-TR100:

- External bonded piezo devices

- Flow thru design

- Serial communication

- Analog output

- No moving parts

- Capable of accurately measuring microflow

- Rapid measurement response (300 sampling time per second)

- Wider measurement range

Benefits of the UFM-TR100:

- Very high accuracy

- High purity

- Remote Operation

- Simplified flow rate monitor

- Intrinsically reliable

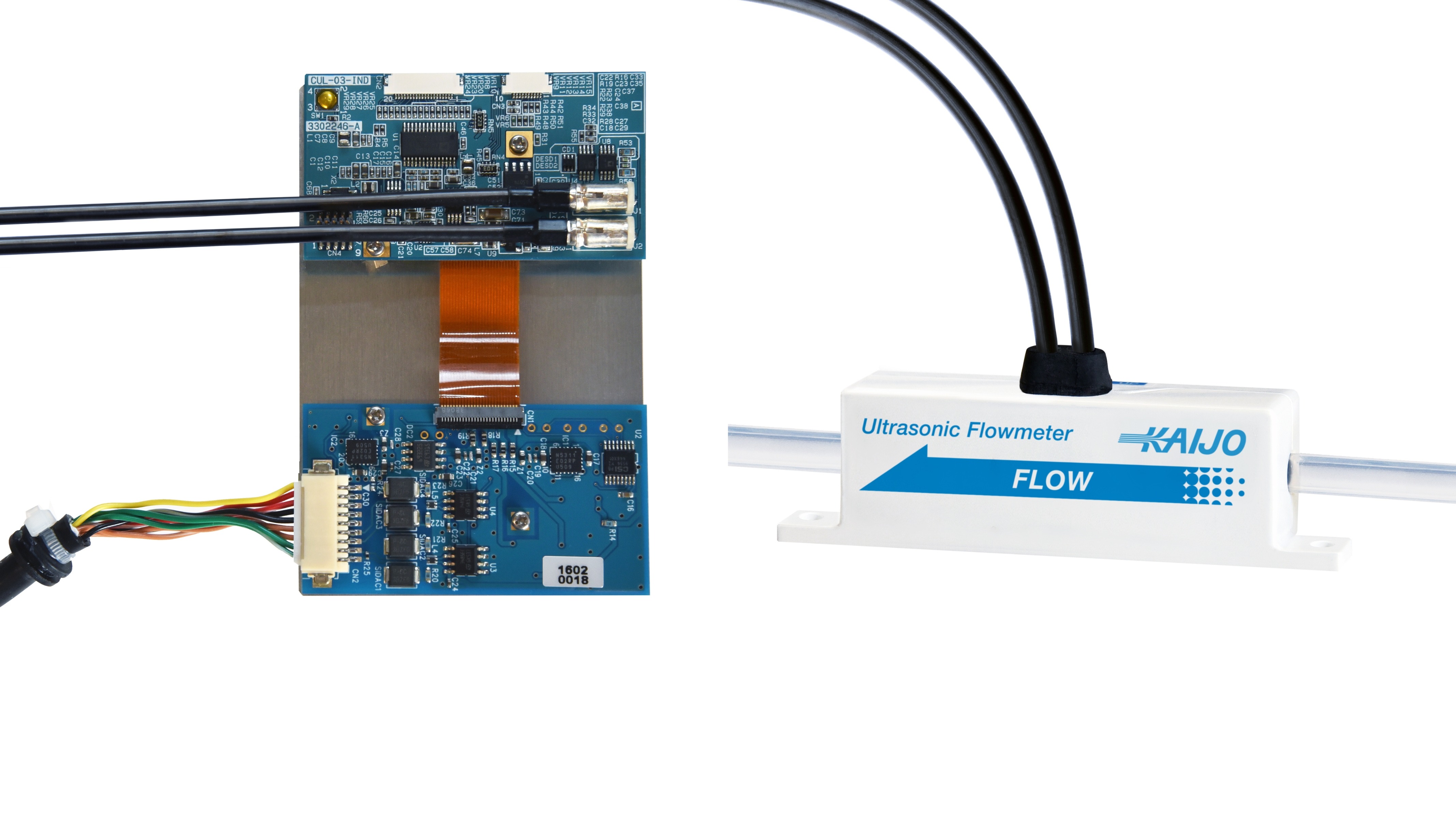

Ultrasonic Liquid Flow Meter UFMe-TR100 System

The UFMe-TR100 converter board is designed to be integrated into a user’s system. It has a smaller footprint and a lower cost compared to the UFM-TR100 system.

Features of the UFMe-TR100:

- Bonded piezo devices

- Interconnect PCB

- Flow thru design

- Serial communication

- No moving parts

Benefits of the UFMe-TR100:

- Very high accuracy

- Lower cost interface

- High purity

- Remote Operation

- Simplified flow rate monitor

- Intrinsically reliable

Ultrasonic Liquid Flow Meter UFM-TR1000 System

Features of the UFM-TR1000:

- Tube diameter configurable

- Clamp-on design

- Wider measurement rangeability

- Low-power

- Analog output

- No moving parts

- Compact design

Benefits of the UFM-TR1000:

- One sensor can adjust to 3/8″, 1/2″ and 3/4″ and 1″ PFA tubing

- High purity

- Intrinsically safe

- Simple installation

- Remote operation

- Intrinsically reliable

Specifications:

| Measurement Method | Digital Cross-Correction | Ultrasonic transit time | |||||

| Model | UFM-TR100 | UFMe-TR100 | UFM-TR1000 | ||||

| Applicable Fluid | Water | ○ | ○ | ○ | |||

| Chemical Liquid (IPA) | ○ | ○ | ○ | ||||

| Other Liquid (Turbidity less than 5000ppm) | – | – | ○ | ||||

| Fluid Condition | Fluid Temperature | 15~80℃ | 15~80℃ | 10~60℃ | |||

| Measurement Range (Flow velocity converted) | – | – | 0~10m/s | ||||

| Measurement Range (Flow Volume) | 1/8inch | 0~1000mL/min | 0~1000mL/min | – | |||

| 1/4inch | 0~4000mL/min | 0~4000mL/min | – | ||||

| 3/8inch | – | – | 0.1~20L/min | ||||

| 1/2inch | – | – | 0.1~40L/min | ||||

| 3/4inch | – | – | 0.2~120L/min | ||||

| 1inch | – | – | 0.2~230L/min | ||||

| Performance | Measurement Accuracy (Flow velocity converted) | Over 1m/s | – | – | ±2%R.D. | ||

| Less than 1m/s | – | – | ±2cm/s | ||||

| Measurement Accuracy (Flow Volume) | 1/8inch | Over 200mL/min | ±0.5%RD* | ±0.5%RD | – | ||

| 0~200mL/min | ±1mL/min | ±1mL/min | – | ||||

| 1/4inch | Over 800mL/min | ±0.5%RD | ±0.5%RD | – | |||

| 0~800mL/min | ±4mL/min | ±4mL/min | – | ||||

| 3/8inch | Over 1900mL/min | – | – | ±2%R.D. | |||

| 0~1900mL/min | – | – | ±40mL/min | ||||

| 1/2inch | Over 4300mL/min | – | – | ±2%R.D. | |||

| 0~4300mL/min | – | – | ±90mL/min | ||||

| 3/4inch | Over 11900mL/min | – | – | ±2%R.D. | |||

| 0~11900mL/min | – | – | ±240mL/min | ||||

| 1inch | Over 11900mL/min | – | – | ±2%R.D. | |||

| 0~11900mL/min | – | – | ±480mL/min | ||||

| Function | Analog Output | DC4~20mA | – | DC4~20mA | |||

| Digital Output | RS-422/485 | RS-422/485 | – | ||||

| Pulse Output (Open collector) | Integrated | ○ | – | ○ | |||

| Normal/Reverse | ○ | – | – | ||||

| Alarm | ○ | – | ○ | ||||

| Power | DC12~24V | DC5V | DC12~30V | ||||

| Installation Requirement | Tube Diameter | Φ1/4, 1/8 inch | Φ1/4, 1/8 inch | Φ1.0, 3/4, 1/2, 3/8 inch | |||

| Tube Material | NEW PFA | NEW PFA | PFA | ||||

| Tube Length | Upper Stream | – | – | More than 10D | |||

| Lower Stream | – | – | More than 5D | ||||

| Sensor Type | Semi-Clamp-On | Clamp-On | |||||

If you have any questions about the ultrasonic liquid flow meter systems or need more information on using them with your application, contact us