Ultrasonic Parts Cleaners

Which Ultrasonic Cleaner is Right for Your Needs?

Your industrial applications demand reliable, efficient solutions. With Kaijo’s ultrasonic cleaners, you can achieve superior cleanliness for automotive, electronics, medical, and aerospace components—all without tedious scrubbing or harsh chemicals.

Ultrasonic cleaners provide precise, effective cleaning of parts and components, removing stubborn deposits such as carbon, grease, and rust. Kaijo’s systems are engineered specifically for high-precision or tight-tolerance parts to ensure consistent, reliable cleaning results.

Why Should You Choose Kaijo’s Ultrasonic Cleaning Systems?

- ✓ Proven Reliability: Consistent results improve your productivity while reducing downtime and maintenance.

- ✓ Precision Results: Effectively clean complicated parts and components thoroughly, eliminating manual scrubbing, thus reducing labor costs.

- ✓ Flexible Solutions: Use cleaning systems tailored to your unique operational needs, ensuring the best results without unnecessary expense.

- ✓ Reduced Operating Costs: Achieve better cleaning results faster, significantly reducing labor costs without using harsh chemicals.

Want to find out which ultrasonic cleaner is best for your industry application?

Contact Us to Discuss Your Requirements

Phenix Hyper Ultrasonic Cleaning Generator

A high-frequency ultrasonic system that provides precise, effective cleaning for your large-scale industrial applications.

Phenix+ Industrial Ultrasonic Generator

Optimized ultrasonic cleaning even in challenging environments, helping you achieve higher quality results every time.

Phenix Legend II High Frequency Ultrasonic Cleaner

High-frequency generator provides effective ultrasonic cleaning performance when facing tough cleaning challenges.

Contact Us to Find the Right System for Your Needs

Articles & Resources on Ultrasonic Parts Cleaning:

Why Should You Use an Industrial Ultrasonic Parts Cleaner?

Why Should You Use an Industrial Ultrasonic Parts Cleaner?

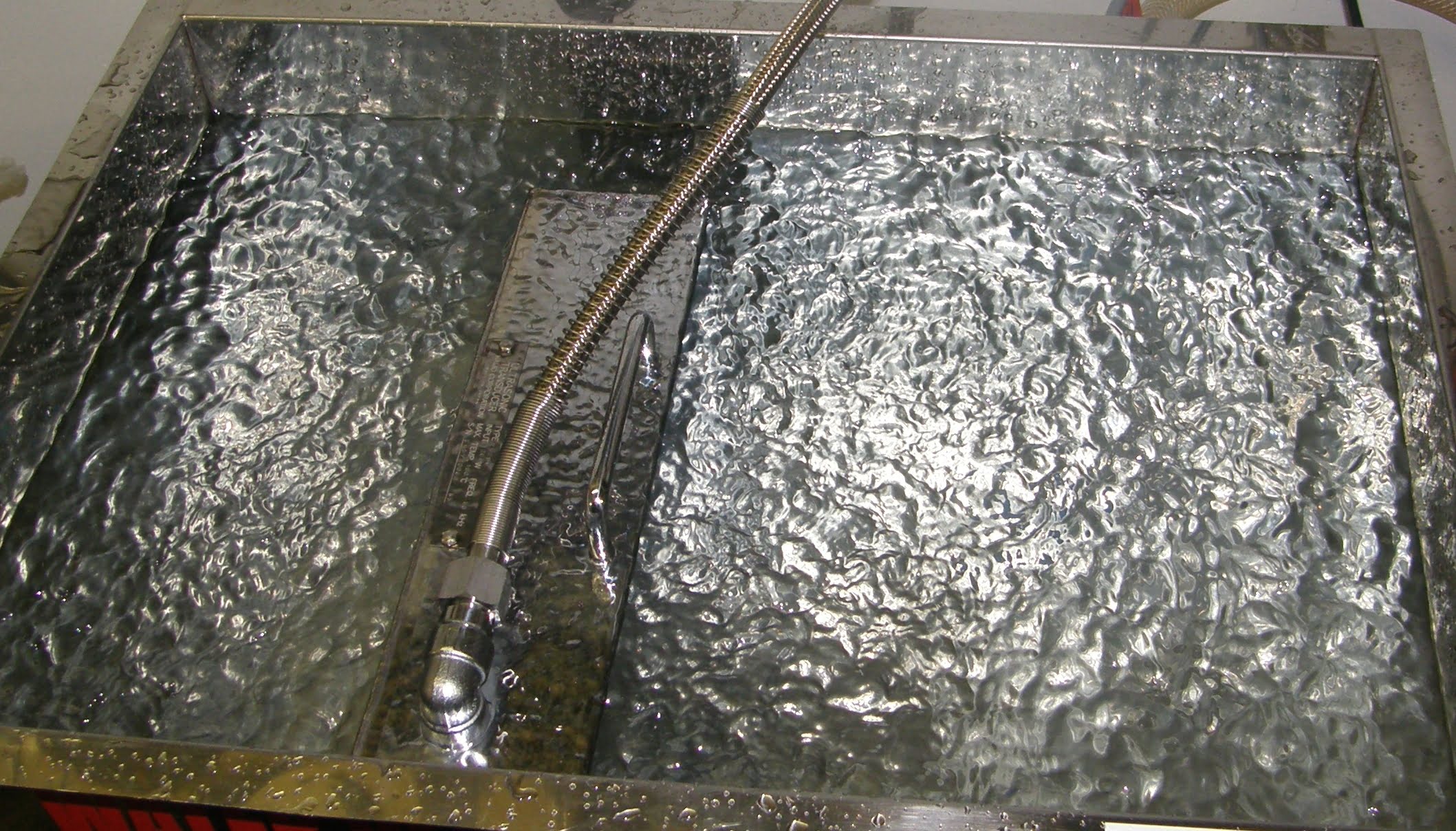

Ultrasonic parts cleaners outperform traditional methods, quickly providing precise, consistent cleaning without manual scrubbing or harsh chemicals. They generate microscopic bubbles from high-frequency sound waves that thoroughly clean parts and components, even in hard-to-reach areas. This process, known as cavitation, ensures high-quality results without manual scrubbing or harsh chemicals, ultimately reducing labor and chemical use costs and improving operational efficiency.

Industries We Serve

Which Industries Can Benefit from Ultrasonic Cleaning?

Kaijo’s industrial ultrasonic cleaners are used in various industries to improve productivity and precision cleaning.

Kaijo’s Expertise as an Ultrasonic Cleaning Manufacturer

Kaijo brings more than 70 years of engineering and manufacturing experience to industrial ultrasonic cleaning solutions. Unlike resellers or private-label suppliers, Kaijo designs, builds, and supports its systems in-house—giving customers higher reliability, long-term performance, and direct access to technical expertise.

Learn more about our capabilities as a leading ultrasonic cleaner manufacturer.

Key Advantages Kaijo Delivers:

-

Full in-house engineering and manufacturing

Every ultrasonic tank, transducer, and generator is designed and produced by Kaijo’s engineers—ensuring tight control over quality, precision, and performance. -

Application-specific cleaning optimization

Systems are tailored for exact materials, part geometries, and contamination types across semiconductor, medical device, automotive, aerospace, and optical manufacturing. -

Advanced frequency and power control technologies

Kaijo’s ultrasonic and megasonic generators, along with the Water Resonance System, provide consistent, stable output for demanding precision-cleaning requirements, including sub-micron particle removal. -

Custom system configurations

Options for tank size, frequency selection, power levels, multi-tank systems, automation, and integration into production lines give engineers flexibility to meet exact process needs. -

Proven reliability in regulated and high-performance industries

Kaijo systems are trusted in environments where process stability, repeatability, and cleanliness directly affect product yield and compliance. -

Direct technical support from manufacturer engineers

Customers receive expert guidance on system selection, process setup, troubleshooting, and long-term maintenance from the engineers who build the equipment.

FAQs About Ultrasonic Parts Cleaners

An ultrasonic parts cleaner is a system that uses ultrasonic sound waves to remove dirt, grime, and contaminants from parts. It is highly effective at cleaning intricate and hard-to-reach areas, making it ideal for precision applications.

To use an ultrasonic parts cleaner, you fill the tank with the appropriate cleaning solution, place the parts inside, and turn on the machine. The ultrasonic waves create bubbles that clean the parts thoroughly.

Ultrasonic parts cleaners are highly effective for removing contaminants from various surfaces. They work well on metals, plastics, ceramics, and other materials, providing consistent, deep cleaning without damaging the parts.

The liquid used in an ultrasonic cleaner is typically water, which may also include a mild cleaning solution designed to enhance the cleaning process. It may vary depending on the material being cleaned and the type of contaminants present.

Ultrasonic cleaning is safe for almost all parts when the correct frequencies and solutions are used. For very delicate or soft materials, special care ensures optimal cleaning without damage.

Ultrasonic cleaning does not damage metal as long as the appropriate settings, frequency, and cleaning solutions are used. It can effectively clean various types of metal surfaces, including aluminum, without damage, making it ideal for precision parts and industrial cleaning applications.

The Phenix Hyper Generator features Hyperwave technology, providing high-frequency, precise cleaning ideal for large-scale industrial applications.

Adaptive Power Control in the Phenix+ Generator optimizes cleaning performance in challenging industrial environments, ensuring efficiency and reliability.