How Ultrasonic Cleaners Optimize Battery Production and Cleaning

June 10, 2025

Table of Contents

- Introduction: Importance of Ultrasonic Cleaners in Battery Manufacturing

- Key Challenges Faced by Manufacturing and Process Engineers in Battery Production

- Fundamentals of Ultrasonic Cleaning Technology

- Applications of Industrial Ultrasonic Cleaners in Battery Production

- Technical Specifications and Insights for Effective Ultrasonic Cleaner Use

- Best Practices for Integrating Ultrasonic Cleaning Technology into Production Workflows

- Measuring the Impact of Ultrasonic Cleaners: Efficiency and Cost-Effectiveness

- Conclusion: Leveraging Ultrasonic Cleaners for Competitive Advantage

1. Introduction: Importance of Ultrasonic Cleaners in Battery Manufacturing

The global demand for high-performance batteries is accelerating significantly, driven primarily by the explosive growth in electric vehicles (EVs), renewable energy storage systems, and increasingly powerful consumer electronics. This demand isn’t just for more batteries, it’s for better batteries with consistent performance, longer lifespans, and enhanced safety profiles. According to BloombergNEF, the energy storage market is projected to expand to 411 gigawatts (or 1,194 gigawatt-hours) by the end of 2030, representing a 15-fold increase from the 27GW (56GWh) available at the end of 2021.

A significant yet frequently overlooked factor essential to meeting these demanding standards is precision cleaning. Contaminants, even at the microscopic level, can significantly degrade battery performance, shorten lifespan, and compromise safety. Traditional cleaning methods often fall short in effectively handling these microscopic contaminants.

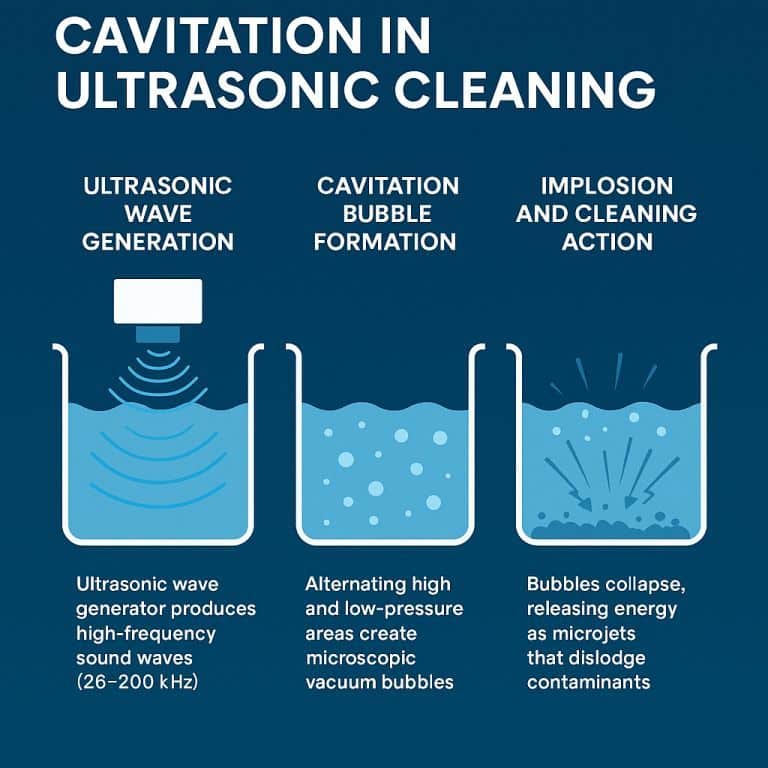

Increasingly, engineers are turning to ultrasonic cleaning systems as the preferred solution. These systems utilize high-frequency sound waves to generate microscopic bubbles. When these bubbles implode, they release powerful, targeted energy, thoroughly removing microscopic contamination from complex geometries and surfaces.

Kaijo’s ultrasonic cleaning technology specifically addresses these rigorous cleanliness requirements. By ensuring superior, precise cleaning beyond traditional methods, ultrasonic cleaners significantly improve battery quality, operational reliability, and manufacturing efficiency.

2. Key Challenges Faced by Manufacturing and Process Engineers in Battery Production

Manufacturing and process engineers in battery production encounter significant contamination challenges that directly influence product quality and operational efficiency.

Top Contamination Issues Affecting Battery Quality and Safety:

- Metal debris: Prevent internal short circuits caused by metal particles from electrode cutting processes.

- Machining oils and lubricants: Ensure electrolyte stability by effectively removing residues from fabrication.

- Dust and ambient particulates: Maintain battery performance consistency by eliminating environmental contaminants.

- Chemical residues: Prevent increased internal resistance by thoroughly removing chemical coatings.

- Fingerprints and organic contaminants: Enhance battery reliability and lifespan by reducing handling-related impurities.

These contaminants, even at microscopic levels, can significantly impact battery functionality, leading to reduced performance, safety issues, and decreased battery longevity. Traditional cleaning methods, such as solvent wiping, compressed air, or basic immersion cleaning, are typically insufficient as they:

- Often leave microscopic contaminants in tight spaces and crevices.

- Fail to remove bound or chemically adhered contaminants.

- Can introduce additional contamination through cleaning media.

- Require significant manual labor and inspection time.

These limitations drive engineers to seek more effective solutions that can deliver consistent results while maintaining production efficiency, which is precisely what ultrasonic cleaning systems provide.

3. Fundamentals of Ultrasonic Cleaning Technology

Ultrasonic cleaners remove contaminants effectively by creating microscopic bubbles using high-frequency sound waves—a process known as cavitation. When these bubbles rapidly collapse, they release powerful jets of energy that thoroughly scrub contaminants from surfaces, even in tight spaces and complex geometries.

Key Benefits of Ultrasonic Cleaning for Battery Manufacturing:

- Microscopic Precision: Effectively cleans even the smallest, hardest-to-reach component areas.

- Uniform Cleaning Results: Delivers consistent cleanliness on every component.

- Reduced Chemical Use: Significantly less reliance on harsh chemicals compared to traditional methods.

- Gentle Yet Powerful Cleaning: Deep cleaning without causing surface damage.

- Reliable and Repeatable Results: Improves production reliability, enhancing both quality and efficiency.

For manufacturing engineers seeking to enhance operational quality and process engineers aiming to reduce cycle times without compromising cleanliness, ultrasonic cleaning technology directly addresses these critical production objectives.

4. Applications of Industrial Ultrasonic Cleaners in Battery Production

Ultrasonic cleaning systems effectively address contamination issues at each stage of battery manufacturing, significantly improving product reliability, assembly quality, and overall throughput. Key application areas include:

Electrode Preparation and Cleaning: Ensuring Optimal Electrical Performance

- Removes microscopic metal debris and manufacturing residues caused by electrode cutting and punching, reducing internal short circuits.

- Effectively eliminates oils and lubricants, ensuring clean electrode surfaces to enhance coating adhesion and overall battery efficiency.

Battery Cell Component Cleaning: Maximizing Reliability and Lifespan

- Gently cleans separator materials to maintain structural integrity and enhance battery longevity.

- Efficiently eliminates particulates from current collectors, terminals, and housing components, directly ensuring consistent battery performance.

Assembly Environment Preparation: Boosting Production Efficiency and Quality

- Cleans production tooling and fixtures thoroughly, significantly reducing the likelihood of contamination-related production defects.

- Prepares assembly equipment and reusable clean room items consistently, supporting higher operational throughput and improved yield.

Integrating ultrasonic cleaning at these critical production stages directly results in:

- Superior product reliability through consistent adherence to cleanliness standards.

- Better manufacturing yields by sharply reducing contamination-related defects.

- Increased production throughput thanks to efficient, streamlined cleaning processes.

- Reduced warranty claims and costs resulting from significantly fewer contamination-related failures.

5. Technical Specifications and Insights for Effective Ultrasonic Cleaner Use

To maximize the effectiveness of ultrasonic cleaners in battery production, understanding and properly configuring key technical parameters is critical:

Ultrasonic Frequency Selection for Battery Components

| Frequency Range | Application | Typical Components | Benefits |

| 38-78 kHz | General cleaning, robust parts | Battery casings, terminals, and structural parts | Powerful cleaning of stubborn contaminants |

| 78-130 kHz | Medium sensitivity cleaning | Electrode materials, medium-sized parts | Balance of cleaning power and gentleness |

| 130-200 kHz | Delicate, precision cleaning | Polymer separators, thin-film components | Gentle removal of sub-micron particles, minimal risk |

Ultrasonic Waveform Selection for Optimized Cleaning

Programmable frequency modulation at 26 kHz or 38 kHz in Kaijo’s Phenix+ industrial ultrasonic generator, produces a stronger and more uniform acoustic pattern for battery cleaning applications.

Kaijo’s 78 kHz Phenix Hyper ultrasonic cleaning generator outputs a standard ultrasonic wave or the proprietary HyperWave. The HyperWave significantly enhances the three-dimensional cleaning of irregularly shaped objects.

Water Treatment to Increase cavitation energy by up to 500%

The Kaijo Water Resonance System (WRS) is a specialized system that significantly improves ultrasonic cleaning results. It optimizes the transmission of ultrasonic energy through water, enhancing cavitation effectiveness to provide superior cleanliness levels without increasing power consumption or risking component damage.

Power Density:

- Lower power densities (10-15 W/gal): Suitable for delicate components to prevent damage.

- Medium power densities (15-25 W/gal): General use for typical battery components.

- Higher power densities (25+ W/gal): Necessary for removing especially tough contaminants like machining oils and residues.

Cleaning Solution Chemistry:

- Aqueous alkaline solutions: Effective against oils and organic contaminants.

- Mild detergents: Recommended for sensitive materials such as separators.

- Specialized formulations: Tailored for specific contaminants commonly encountered in battery production.

Process Parameters:

- Temperature control: Typically set between 40-60°C (104-140°F) to optimize cleaning efficiency.

- Cycle times: Standard cleaning operations typically range from 2-5 minutes.

- Filtration and Bath Maintenance: Continuous filtration extends bath life and maintains cleaning effectiveness.

- Rinse and Dry Processes: Essential for avoiding residual contamination from cleaning solutions, thereby enhancing overall cleanliness and component reliability.

Integrating these specifications into your production processes ensures consistent, high-quality cleaning outcomes, directly enhancing battery performance and manufacturing efficiency.

Kaijo’s multi-frequency systems, such as the Quava Multi series ultrasonic frequency generator, allow production lines to clean various components with a single system by adjusting frequency settings to match specific cleaning requirements. This versatility is particularly valuable in facilities that manufacture multiple battery types or sizes, where component dimensions and materials may vary significantly between product lines.

6. Best Practices for Integrating Ultrasonic Cleaning Technology into Production Workflows

Successfully implementing ultrasonic cleaning into battery manufacturing processes requires precise strategic planning and structured operational steps.

Integration Planning Steps:

- Process Mapping: Identify critical cleaning stages to pinpoint precisely where ultrasonic cleaning adds optimal value in your production workflow.

- Space Optimization: Strategically position ultrasonic cleaning stations to minimize unnecessary handling and transportation of components.

- Automation Integration: Integrate automated loading and unloading systems to reduce manual labor and boost overall throughput capacity.

- Throughput Alignment: Match the ultrasonic cleaning system capacity with the facility’s overall production volume targets to ensure seamless workflow integration.

Operational Best Practices:

- Regular Bath Maintenance: Monitor and replenish cleaning solutions regularly to maintain high cleaning performance.

- Continuous Filtration: Implement robust filtration systems to prolong bath life, maintain cleanliness, and maximize effectiveness.

- Optimized Fixturing: Utilize specialized fixtures that maximize ultrasonic exposure and prevent part shadowing or stacking, ensuring uniform cleaning results.

- Process Validation: Regularly conduct visual inspections and analytical tests for component cleanliness to confirm ultrasonic cleaning effectiveness.

- Operator Training: Offer comprehensive training programs covering system operation, routine maintenance, and troubleshooting to empower operators and increase operational reliability.

Common Troubleshooting Issues and Solutions:

| Problem | Potential Causes | Recommended Solutions |

| Inconsistent cleaning results | Depleted cleaning solution; improper part loading | Regular solution checks; standardized loading procedures |

| Equipment performance decline | Aging transducers, power supply issues | Scheduled preventive maintenance, regular generator calibration |

| Excessive cleaning cycle times | Insufficient power, incorrect frequency, non-optimized waveform, contaminated solution | Optimize frequency and waveform; manage solution quality |

| Part damage during cleaning | Excessive ultrasonic power, incorrect frequency, non-optimized waveform, inadequate fixturing | Optimize frequency and waveform; enhance fixture designs |

By implementing these strategic steps and operational best practices, engineers can significantly enhance the reliability, efficiency, and impact of their ultrasonic cleaning processes, thereby achieving consistently higher production quality and reducing overall operational costs.

7. Measuring the Impact of Ultrasonic Cleaners: Efficiency and Cost-Effectiveness

To justify investment and optimize battery manufacturing operations, quantifying the effectiveness of ultrasonic cleaning systems is critical. Clear performance metrics make it easy to identify quality improvements, operational efficiencies, and cost reduction outcomes resulting from the adoption of ultrasonic cleaning.

A Real-World ROI Example:

| Metric | Traditional Method | Ultrasonic Cleaning | Annual Savings |

| Defect Rate (%) | 8% | 3% | 5% Improvement |

| Monthly Rework Cost | $12,000 | $4,500 | $7,500 |

| Labor Hours (monthly cleaning) | 200 hours | 80 hours | 120 hours |

| Labor Cost (@ $35/hr) | $7,000 | $2,800 | $4,200 |

| Chemical and Disposal Cost (Monthly) | $2,500 | Minimal (~$100) | $2,400 |

| Total Annual Savings | $169,200 |

Key Performance Metrics to Monitor:

- Quality Improvements:

- Significant reduction in contamination-related product defects

- Permanent reduction in final testing failure rates

- Consistent, predictable battery performance outcomes

- Operational Efficiency:

- Shorter cycle times for cleaning operations, directly boosting production volume

- Lower labor requirements, enabling staff to focus on other value-added tasks

- Reduced downtime and minimized rework related to cleanliness issues

- Cost Reductions:

- Major decrease in chemical consumption and related expenses

- Reduced water usage and lower associated operational costs

- Extended lifespan of manufacturing equipment due to optimized usage and improved maintenance practices

Benchmarking and Continuous Improvement:

- Regularly benchmark ultrasonic cleaning system performance against industry standards or comparable manufacturing processes to identify ongoing optimization areas.

- Implement digital analytics and real-time dashboards for proactive monitoring of cleanliness standards, equipment efficiency, and resource utilization, allowing rapid improvements and consistent operational excellence.

Highlighting these measurable operational improvements underscores how thoroughly integrating into your production workflow can deliver substantial competitive and financial advantages, typically achieving a full return on investment (ROI) within 6 to 12 months.

8. Conclusion: Leveraging Ultrasonic Cleaners for Competitive Advantage

The integration of ultrasonic cleaning in battery production is more than a technical enhancement—it’s a strategic imperative for manufacturers seeking to meet the growing demand for high-performance, high-reliability energy storage solutions.

For manufacturing and process engineers, offer measurable benefits across key operational areas:

- Improved product quality through precision cleaning that reduces defect rates.

- Operational efficiency gains via reduced cycle times and simplified workflows.

- Significant cost savings from lower labor, water, and chemical usage.

- Faster ROI, often realized within 6–12 months of implementation.

By using ultrasonic cleaning systems, manufacturers position themselves to meet increasingly stringent quality standards and customer expectations, particularly in competitive sectors such as electric vehicles, renewable energy, and advanced electronics.

Kaijo’s portfolio of ultrasonic cleaning solutions, including Phenix Hyper and Phenix+ generators and turnkey systems, provides manufacturers with the tools to deliver the microscopic cleanliness required for next-generation batteries consistently. These systems combine flexible frequency control, energy efficiency, and process automation to support scalable, future-ready production environments.

Take the Next Step

Ready to enhance your battery manufacturing operations? Contact Kaijo today to schedule a free consultation. Our technical team will assess your production workflow and recommend a tailored ultrasonic cleaning solution that aligns with your quality, throughput, and cost-efficiency goals.

Don’t let outdated cleaning methods limit your competitive edge, use ultrasonic cleaning to achieve excellence in every cell.