How Ultrasonic Cleaning Systems Enable Industry 4.0 Manufacturing

Written by: Michael Danese | February 5, 2026

Summary: Ultrasonic cleaning systems play a measurable role in Industry 4.0 manufacturing by enabling automated, repeatable contamination removal, directly impacting yield, throughput, and process validation. Cleaning operations must deliver the same level of control, consistency, and data visibility as other critical manufacturing processes.

Summary: Ultrasonic cleaning systems play a measurable role in Industry 4.0 manufacturing by enabling automated, repeatable contamination removal, directly impacting yield, throughput, and process validation. Cleaning operations must deliver the same level of control, consistency, and data visibility as other critical manufacturing processes.

Table of Contents

- The Role of Ultrasonic Cleaning in Industry 4.0 Manufacturing

- Addressing Process Efficiency Challenges with Ultrasonic Cleaning Systems

- Ensuring Consistent Quality in Data-Driven Manufacturing Environments

- Supporting Regulatory Compliance Across Multiple Industries

- Enabling Data-Driven Decision-Making and Continuous Improvement

- How Kaijo’s Ultrasonic Cleaning Systems Support Industry 4.0 Integration

- Frequently Asked Questions

1. The Role of Ultrasonic Cleaning in Industry 4.0 Manufacturing

In Industry 4.0 manufacturing, surface cleanliness directly affects yield, reliability, and process stability. Adhesion failures, solder defects, coating delamination, and wafer rejects are frequently traced back to inconsistent contamination removal—yet cleaning processes are often overlooked when manufacturers modernize production lines.

Industry 4.0 is built on three core principles: connectivity between systems, automation of manual processes, and data-driven decision-making. Cleaning operations must align with these principles to avoid becoming bottlenecks. Ultrasonic cleaning systems function as process enablers, not auxiliary steps, delivering controlled, physics-based cleaning that removes oils, particulates, and residues from complex geometries and blind features that traditional methods cannot reach.

Ultrasonic cleaning technology uses high-frequency sound waves to create microscopic cavitation bubbles within a cleaning solution. When these bubbles collapse, they generate localized energy that dislodges contaminants without damaging parts. Because the cleaning mechanism depends on controlled energy rather than operator technique, results remain consistent across shifts, batches, and facilities.

Modern ultrasonic generators integrate naturally into automated manufacturing environments. Digital controls, remote monitoring, and parameter logging support traceability and validation—capabilities that align directly with smart factory requirements. Manufacturers pursuing Industry 4.0 strategies increasingly require cleaning processes that deliver batch-to-batch consistency, repeatability, and documented performance.

2. Addressing Process Efficiency Challenges with Ultrasonic Cleaning Systems

Process efficiency is a defining metric in competitive manufacturing. Engineers are under constant pressure to reduce cycle times, increase throughput, and minimize rework without compromising quality. Ultrasonic cleaning systemsaddress these challenges directly by eliminating manual steps, accelerating cleaning cycles, and integrating with automated production lines.

Key efficiency improvements ultrasonic cleaning systems deliver:

- Eliminates operator variability and reduces labor costsby removing manual scrubbing, extended soak times, and repetitive rinse cycles. Parts are loaded into tanks or inline systems, and ultrasonic energy uniformly cleans them.

- Cuts cleaning time from hours to minutes, increasing throughput. Case studies have demonstrated cycle-time reductions of up to 50% and significant water savings compared with conventional cleaning methods, depending on the application and process design.

- Enables fully unattended cleaningwithin robotic and conveyorized lines. Modern ultrasonic systems integrate with automation, allowing parts to be loaded, cleaned, rinsed, and dried without human handling—an essential requirement for continuous production environments.

- Delivers identical resultsacross thousands of parts, shifts, and facilities. Frequency, power, temperature, and cycle duration remain controlled, producing predictable outcomes that support lean manufacturing and high-volume production.

Manufacturers implementing ultrasonic cleaning systems report measurable efficiency gains:

- Reduced chemical usagethrough shorter cleaning cycles

• Lower operational costs from decreased labor and consumables

• Improved product quality through superior contamination removal

• Minimized environmental impact with reduced water and chemical consumption

These systems are deployed across aerospace, automotive, semiconductor, medical, and precision manufacturing environments.

3. Ensuring Consistent Quality in Data-Driven Manufacturing Environments

In data-driven manufacturing, quality consistency separates high-performing operations from those burdened by scrap, rework, and returns. Surface cleanliness plays a critical role in the success of downstream processes—from coating adhesion to solderability to sterilization effectiveness.

Ultrasonic cleaning systems provide repeatable, validated cleaning outcomes because the process is governed by controlled physical parameters rather than operator judgment. When frequency, power, temperature, and time are held within defined limits, cleaning results remain consistent and auditable.

Contaminated surfaces create failures downstream. Oil residues inhibit coating adhesion. Particulates on circuit boards lead to electrical shorts. Biological residues compromise sterilization in medical manufacturing.

In semiconductor fabrication, cleanliness requirements are measured at the nanometer scale. Megasonic cleaning systems operating above 400 kHz generate smaller cavitation bubbles that remove ultra-fine particles without damaging delicate wafer surfaces. This capability is essential for advanced wafer processing and yield protection.

Modern ultrasonic generators integrate with manufacturing execution systems (MES) and statistical process control (SPC) platforms. Process parameters such as power output, frequency stability, and cycle duration can be logged automatically.

Engineers can establish control limits, correlate cleaning parameters with downstream quality metrics, and support continuous improvement initiatives.

4. Supporting Regulatory Compliance Across Multiple Industries

Regulatory requirements continue to expand across electronics, automotive, aerospace, and medical manufacturing. Standards such as RoHS, REACH, IATF 16949, AS9100, FDA regulations, and ISO 13485 increasingly require documented, validated cleaning processes.

Ultrasonic cleaning systems support compliance through precise control, traceability, and repeatability. Digital generators track operating parameters that can be stored and linked to production lots or serial numbers. Once validated, cleaning processes can be locked in place, with deviations triggering alerts.

Automated ultrasonic cleaning reduces reliance on operator-dependent procedures, simplifying audit preparation and reducing documentation burden. The repeatability of the process supports contamination control requirements across regulated industries.

PFAS (per- and polyfluoroalkyl substances) present an emerging compliance challenge due to their persistence and resistance to conventional removal methods. These “forever chemicals” contain strong carbon-fluorine bonds that are extremely difficult to break.

Research indicates that ultrasonic and megasonic energy can assist in removing PFAS contamination from solid surfaces by enhancing desorption and mechanical separation, particularly when combined with optimized process conditions. Kaijo’s Phenix Hyper ultrasonic cleaning generator is being applied to PFAS-contaminated surface cleaning use cases where chemical-free cleaning is preferred, and where ultrasonic energy can help dislodge and separate PFAS residues under optimized conditions. Results depend on the surface, PFAS type, and process configuration.

5. Enabling Data-Driven Decision-Making and Continuous Improvement

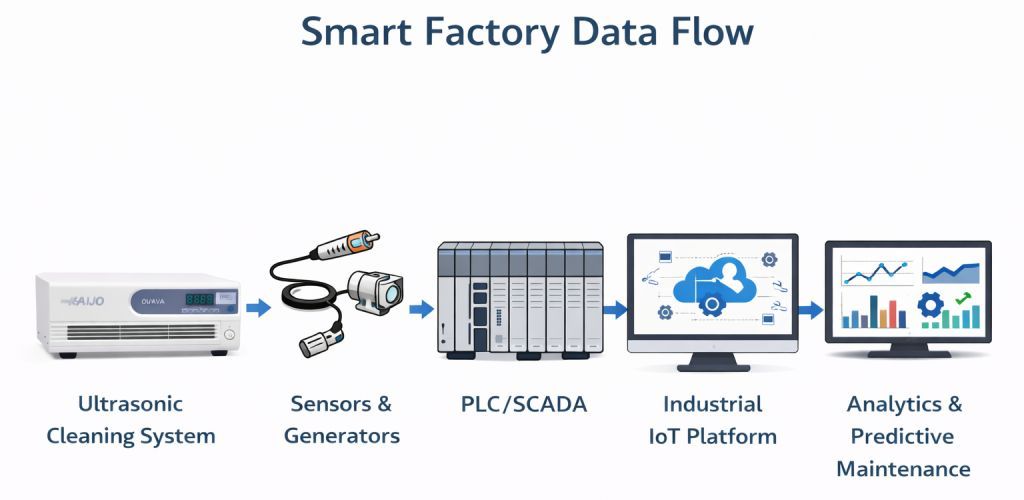

Industry 4.0 manufacturing depends on actionable data to optimize processes, predict maintenance needs, and reduce downtime. When integrated into factory networks, ultrasonic cleaning systems become data-generating assets rather than isolated equipment.

Modern ultrasonic generators communicate with PLCs, SCADA systems, and industrial IoT platforms. Parameters commonly monitored include frequency stability, power output, solution temperature, cycle duration, tank levels, and chemistry concentration.

What Engineers Gain from Cleaning Process Data:

- Faster root-cause analysis of downstream defects through parameter correlation

• Reduced trial-and-error during process optimization with quantitative evidence

• Predictable maintenance scheduling and reduced unplanned downtime

• Process validation documentation for regulatory compliance

• Cross-facility standardization with replicated parameter sets

By correlating cleaning parameters with quality outcomes, engineers make evidence-based adjustments. Small changes in cycle time or ultrasonic power may eliminate downstream defects or reduce energy consumption without compromising cleanliness.

Operational data also supports predictive maintenance. Gradual changes in power draw or frequency stability can signal transducer or generator degradation before failure occurs, enabling maintenance during planned downtime.

6. How Kaijo’s Ultrasonic Cleaning Systems Support Industry 4.0 Integration

Kaijo designs ultrasonic cleaning systems specifically for manufacturers implementing automated, data-driven production environments where process control and repeatability are non-negotiable. The company supports both industrial ultrasonic cleaning and megasonic wafer cleaning applications.

Kaijo’s advanced generator platforms, including the Phenix Hyper and Phenix+, provide stable frequency control, adjustable power output, and digital interfaces compatible with Industry 4.0 requirements. These systems deliver controlled cavitation energy for demanding contamination challenges, including PFAS residues, without excessive heat or harsh chemicals.

Kaijo’s Water Resonance System (WRS) and turnkey ultrasonic cleaning solutions provide scalable options for diverse industries. Systems are deployed across:

- Semiconductor(megasonic wafer cleaning)

• Automotive (engine components, transmission parts)

• Medical (surgical instruments, implantable devices)

• Aerospace (critical component preparation)

• Precision optics (LCD screens, solar panels)

Kaijo’s systems operate as standalone equipment or integrate into automated production lines. Engineers receive technical guidance on frequency selection, power requirements, tank design, and system integration—ensuring each ultrasonic cleaning system is matched to application-specific requirements.

7. Frequently Asked Questions

Q1: How do ultrasonic cleaning systems support Industry 4.0 manufacturing strategies?

Ultrasonic cleaning systems support Industry 4.0 by providing automated, repeatable cleaning processes with digital connectivity for real-time monitoring, process optimization, and quality control. Modern generators integrate with PLCs, MES, and SCADA systems, enabling parameter logging, traceability, and data-driven process adjustments that align with smart factory requirements.

Q2: Which industries benefit most from ultrasonic cleaning technology?

Industries with high cleanliness standards and regulatory requirements benefit most, including:

- Semiconductor fabrication (wafer cleaning at nanometer-scale cleanliness)

- Medical device manufacturing (validated cleaning for surgical instruments)

- Aerospace (precision component preparation)

- Automotive (contamination removal from engine and transmission parts)

- Precision optics (LCD screens, solar panels)

Q3: Can ultrasonic cleaning systems integrate with smart factory platforms?

Yes. Modern ultrasonic cleaning systems include digital interfaces compatible with PLCs, SCADA systems, and industrial IoT platforms. These interfaces enable automated operation, remote monitoring, predictive maintenance alerts, and integration with broader factory automation architectures.

Q4: How does ultrasonic cleaning improve quality consistency in high-volume production?

Ultrasonic cleaning eliminates operator variability by using controlled physical parameters (frequency, power, temperature, time) rather than a manual technique. This produces identical cleanliness results across production runs, shifts, and facilities—supporting statistical process control and quality management systems.

Q5: What should engineers evaluate when selecting ultrasonic cleaning systems for Industry 4.0 environments?

Key evaluation criteria include:

- Frequency selection (lower frequencies for heavy contamination; higher frequencies for precision cleaning)

- Power requirements (adequate ultrasonic power for part geometry and contamination level)

- Automation compatibility (integration with existing robotics and conveyor systems)

- Data connectivity (digital interfaces for process monitoring and control)

- Scalability (ability to replicate across multiple production facilities)

- Validation support (documentation and technical assistance for process qualification)

Implement Ultrasonic Cleaning in Your Industry 4.0 Strategy

Ultrasonic cleaning systems enable the consistency, automation, and data integration required by Industry 4.0 manufacturing. By reducing variability, supporting regulatory compliance, and generating actionable process data, they transform cleaning from a secondary step into a strategic manufacturing operation that directly impacts yield, throughput, and quality.

Whether you’re addressing contamination challenges in semiconductor fabrication, preparing aerospace components for assembly, or meeting medical device cleanliness requirements, Kaijo’s ultrasonic cleaning systems deliver measurable value.

Key Takeaways

- Ultrasonic cleaning systems enable automated, repeatable contamination removal in Industry 4.0 manufacturing

- Integration with PLC, MES, and SPC systems supports traceability, quality control, and data-driven optimization

- Megasonic cleaning systems operating above 400 kHz support nanometer-scale contamination control for semiconductor wafers

- Cleaning process data enables predictive maintenance and continuous improvement initiatives

- Properly configured ultrasonic cleaning systems support regulatory compliance efforts

Ready to optimize your cleaning processes?Contact Kaijo to discuss your specific application requirements with a technical specialist, or explore our complete line of ultrasonic cleaning solutions.