How Ultrasonic Cleaning Transducers Work

September 27, 2018

Ultrasonic cleaning transducers convert the high-frequency electric signal of an ultrasonic cleaning system to sound waves in the cleaning solution. These systems are made up of an ultrasonic generator, a transducer and a tank to hold the cleaning solution. Low frequencies from 20 kHz to about 160 kHz are used for cleaning heavy, hard to clean contamination from robust parts while higher frequencies up to 2MHz are used for gentle cleaning of delicate parts.

convert the high-frequency electric signal of an ultrasonic cleaning system to sound waves in the cleaning solution. These systems are made up of an ultrasonic generator, a transducer and a tank to hold the cleaning solution. Low frequencies from 20 kHz to about 160 kHz are used for cleaning heavy, hard to clean contamination from robust parts while higher frequencies up to 2MHz are used for gentle cleaning of delicate parts.

The ultrasonic generator produces an electric signal whose voltage varies at the selected ultrasonic frequency. When the voltage is applied to piezoelectric crystals within Kaijo’s transducers, the crystals change shape slightly. As the voltage rises and falls, the crystals lengthen and shorten. As a result, the metal plate attached to the crystals vibrates in tune with the ultrasonic frequency. When the transducer is immersed in the cleaning solution, the vibration of the metal plate produces the ultrasonic waves.

Ultrasonic Cleaning Transducer Features

Ultrasonic transducers have to generate an equal and consistent distribution of sound waves in the cleaning solution while withstanding the vibrations, temperature and cleaning action of the ultrasonic cleaning system. The ultrasonic sound waves create high-energy cavitation bubbles in the cleaning solution, and while these bubbles are responsible for the cleaning action, they can also eat away at materials that are not properly selected. The cleaning solution may contain mild solvents and can be heated for faster cleaning. The ultrasonic transducers have to operate reliably in this environment.

The housing of Kaijo ultrasonic cleaning transducers is made of 316L polished stainless steel so the transducers are not affected by the cleaning solution and can withstand the potential pitting action of the cavitation bubbles. They are hermetically sealed and can operate in cleaning solutions at up to 100 degrees Centigrade. The lower frequency range transducers are available at 600 W and 1200 W while the higher frequency units can handle up to 1200 W. The relatively high power ratings ensure that all parts of the cleaning solution tank receive an even level of ultrasonic waves.

Types of Ultrasonic Cleaning Transducers

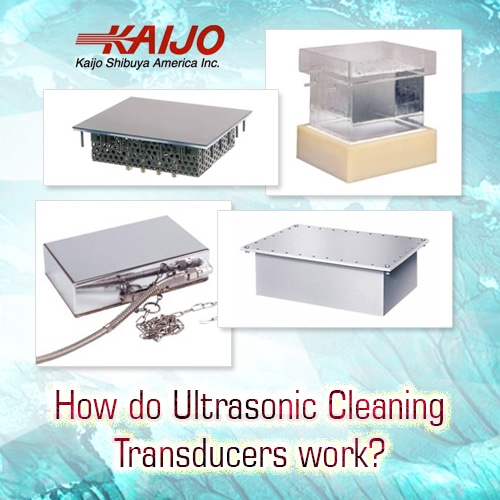

Depending on the cleaning application and the different kinds of cleaning required, either immersible, bolt-on or mounted types of transducers can be used. The immersible ultrasonic transducers are independent units and are the most flexible in their application. The bolt-on units are for semi-permanent placement on a cleaning tank and the mounted units are integrated in the tank. Each type is functionally the same but the mounting method is determined by how the ultrasonic cleaning system will be used.

For cleaning applications using existing tanks, the immersible or bolt-on types of transducer are the most appropriate. The immersible type is more flexible and can be placed into different tanks or different transducers can be used for the same tank. These immersible transducers simply attach to the ultrasonic generator with a cable and they can then be moved around and placed into the cleaning solution without any installation procedure. The bolt-on type of transducer is more appropriate for cleaning applications of one particular kind. If the same kinds of parts are cleaned regularly, the frequency, power and cleaning tanks remain unchanged. In this case, the transducers can be bolted onto the tanks and left there. Transducers can be mounted along the walls of the tanks or on the bottom.

Mounted transducers are often integrated into a turnkey system that customers can buy for a specific application. These systems are less flexible but everything needed is functionally matched and included in the turnkey package and offers a cost effective solution.

No matter what the cleaning application requirements are, Kaijo can help customers select ultrasonic products such as generators and transducers or recommend complete systems that will satisfy their needs. Contact Kaijo for a free consultation and quote at 408 675-5575.