How to Specify Equipment Size and Options for an Ultrasonic Cleaner

March 26, 2019

While selecting the right operating frequency for industrial ultrasonic cleaners is important, the equipment size and options are critical for obtaining excellent cleaning performance. Depending on the cleaning application, either a flexible system or a system designed for one particular task may be best, and selecting the corresponding options will influence how the system can be used. Ideally the equipment size and options chosen match to provide an ultrasonic cleaning system with superior cleaning capabilities.

While selecting the right operating frequency for industrial ultrasonic cleaners is important, the equipment size and options are critical for obtaining excellent cleaning performance. Depending on the cleaning application, either a flexible system or a system designed for one particular task may be best, and selecting the corresponding options will influence how the system can be used. Ideally the equipment size and options chosen match to provide an ultrasonic cleaning system with superior cleaning capabilities.

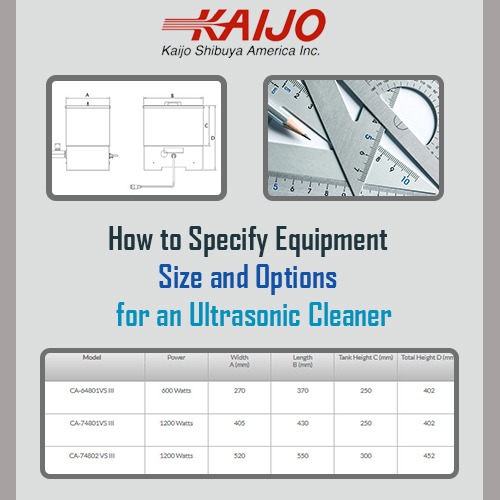

Choosing the Equipment Size

In ultrasonic cleaning systems, the parts to be cleaned are immersed in a solution contained in ultrasonic cleaning tanks. The tank has to be large enough to fit the largest part but the power of the system has to be adequate to fill the tank with ultrasonic sound waves. Sometimes custom tanks are needed for objects with an unusual shape. For example, a long, narrow tank may be large enough for a long, thin pole and a square, shallow tank can clean a part shaped like a disc. When the tank matches the shapes of the parts to be cleaned, there is less cleaning solution and a lower power requirement.

Small or delicate parts may be damaged by vibrations if they come into contact with the walls or bottom of the cleaning tank. The ultrasonic sound waves are too high a frequency to make the parts vibrate directly but they may trigger lower-frequency harmonics in the cleaning solution and in the tank sides. Placing these parts in a basket eliminates the possibility of vibration damage. In this case, the basket has to be large enough to hold the parts and the tank has to be large enough to hold the basket.

Transducer Selection

Transducers convert the electric frequency signal from the ultrasonic generator into sound waves in the cleaning solution. They can be immersible, bolt on or permanently mounted on the cleaning tank. Immersible transducers are the most flexible because they are independent units that can be placed into any tank, wherever they are needed. Bolt-on units can be replaced with other transducers when required. Mounted transducers are usually part of a turn key system and can’t easily be changed. Depending on the cleaning application and whether the ultrasonic system is used for one or many different cleaning tasks, the selection of the transducer should reflect the amount of flexibility needed.

Ultrasonic Generator Options

Ultrasonic cleaning generators produce an electrical signal at the ultrasonic frequency. A generator can be designed to produce only one frequency, several frequencies or a range of frequencies. Depending on the cleaning application, different frequencies might be required. If only lightly contaminated delicate parts are cleaned, a single high frequency is probably enough. If the parts are more rugged and contamination is not too heavy, a mid-range frequency will clean adequately. For metal parts without a delicate surface finish and for removing heavy dirt and grime, the low frequencies are appropriate. If multiple uses are being considered, a multi-frequency generator is needed.

Choosing the Right System

Ultrasonic cleaning systems can be turn-key or customers can assemble them from individual components. Turn-key systems are configured so the parts match, and they are an excellent option for new systems. When retrofitting existing systems, purchasing individual components is often more cost effective. For example, if there are existing cleaning tanks, an ultrasonic generator together with an immersible transducer may be all that’s needed.

No matter what the ultrasonic cleaning application, Kaijo offers free consultation services and supplies industrial ultrasonic cleaners that serve the needs of companies in many different industries. Kaijo can advise which components, systems and configuration is the best for a particular cleaning application and can then offer equipment from its complete line of ultrasonic cleaners.