How Ultrasonic Transducers Work and Are Used in Industrial Cleaning Applications

July 8, 2019

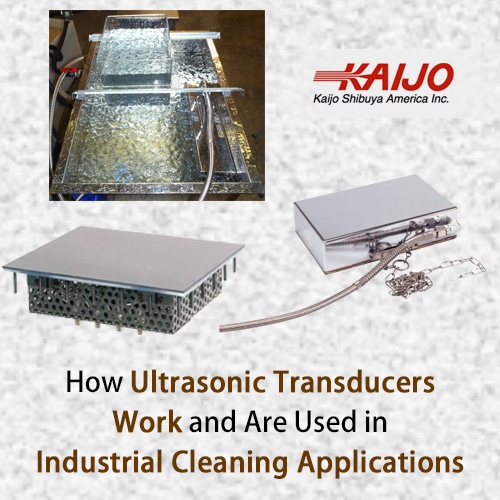

In industrial ultrasonic cleaning systems, a generator produces the electric high-frequency signal and a transducer converts the signal into physical sound waves in the cleaning solution. Depending on the application, ultrasonic cleaning transducers can handle different frequencies and deliver enough power to fill the cleaning tank with ultrasonic waves. For existing tanks, moveable immersible transducers are the most flexible solution while new tanks and turnkey often have permanently installed transducers.

In industrial ultrasonic cleaning systems, a generator produces the electric high-frequency signal and a transducer converts the signal into physical sound waves in the cleaning solution. Depending on the application, ultrasonic cleaning transducers can handle different frequencies and deliver enough power to fill the cleaning tank with ultrasonic waves. For existing tanks, moveable immersible transducers are the most flexible solution while new tanks and turnkey often have permanently installed transducers.

How the Transducer Produces Cleaning Action

Ultrasonic cleaning transducers consist of a thick metal plate and active parts that vibrate when an electrical signal is applied. For piezoelectric transducers, the active parts consist of piezoelectric material that changes shape in tune with the frequency of the electric signal. For magnetostrictive transducers, metallic plates vibrate in tune with the high-frequency magnetic field created by the electric signal. In either case, the vibrations are transmitted to the heavy metal plate that then transmits the vibrations to the cleaning solution.

When the ultrasonic waves pass from the transducer’s metal plate through the cleaning solution, the wave troughs create low pressure regions that produce cavitation bubbles. The bubbles form during the wave troughs and collapse at the subsequent wave peaks, releasing jets of energy. The collapse of the bubbles scrubs the parts to be cleaned and dislodges dirt and contaminants from the part surface. In this way, the transducer turns the electric signal from the ultrasonic generator into physical scrubbing and cleaning action.

Piezoelectric Versus Magnetostrictive Transducers

Historically piezoelectric materials such as quartz crystals were delicate and had a relatively short lifetime when used in ultrasonic cleaning applications. Magnetostrictive transducers consist of metal plates and coils of wire that are not easily damaged. At one time the latter were used in ultrasonic cleaning systems almost exclusively because they were more reliable.

New advances in piezoelectric materials contributed to the re-emergence of the piezoelectric transducer as the technology of choice. The new materials are rugged and they can be used up to the highest megahertz frequencies. The vibrating function of magnetostrictive transducers depends on the size of the metal plates. Higher frequencies require shorter plates and there is a limit to how much the size of the plates can be reduced. As a result, magnetostrictive transducers can only be used for the lower frequencies.

Types of Transducers

The type of transducer required for a particular cleaning application is influenced by the cleaning tank and the size of the parts to be cleaned. Portable transducers can be placed into existing tanks while new installations may come with permanently installed units. For large parts, the corresponding tank may need several transducers to evenly fill the whole volume of cleaning solution with ultrasonic sound waves.

An immersible ultrasonic transducer is an independent unit with a sealed case and a water proof cable attached. These transducers can be placed into any ultrasonic cleaning tank to produce the required ultrasonic sound waves. The cable is attached to a matched ultrasonic generator to complete the ultrasonic cleaning installation.

For new installations with a new cleaning solution tank, a bolt-on transducer is often the most appropriate solution. The transducer can be bolted onto the sides or the bottom of the tank and it can be exchanged if the cleaning application requirements change and a model with different characteristics is needed.

Turnkey ultrasonic cleaning systems often have permanently mounted transducers because they are self-sufficient systems ready to begin operation. Smaller systems may come as an integrated single unit with the appropriate transducer included.

Kaijo provides different types of ultrasonic cleaning transducers and systems for operations from the lowest to the highest frequencies. For large tanks, the company can advise customers on the deployment of several transducers in a configuration that will deliver the required cleaning performance. Contact Kaijo for a free consultation on selecting the right ultrasonic transducer and system for your specific industrial cleaning application.