How Ultrasonics Are Used to Clean High Purity Ceramic Parts

April 19, 2022

While ultrasonics can clean high purity ceramic parts quickly and completely, the special characteristics and surfaces of these parts make it critical to use the right ultrasonic cleaning system. The frequencies and power have to be matched to the parts and to the cleaning application. The waveform and modulation generated by the ultrasonic cleaner affects cleaning performance. The cleaning tank solution and temperature are also important factors for cleaning certain parts. All these factors have to be considered to get a correctly configured system. An experienced ultrasonic cleaning manufacturer can evaluate high purity ceramic cleaning applications and recommend the appropriate system configuration that delivers the required cleaning performance.

While ultrasonics can clean high purity ceramic parts quickly and completely, the special characteristics and surfaces of these parts make it critical to use the right ultrasonic cleaning system. The frequencies and power have to be matched to the parts and to the cleaning application. The waveform and modulation generated by the ultrasonic cleaner affects cleaning performance. The cleaning tank solution and temperature are also important factors for cleaning certain parts. All these factors have to be considered to get a correctly configured system. An experienced ultrasonic cleaning manufacturer can evaluate high purity ceramic cleaning applications and recommend the appropriate system configuration that delivers the required cleaning performance.

The Right Frequency Helps Clean Rapidly While Avoiding Damage to Parts

High purity ceramic parts include devices for the medical industry, semiconductor manufacturing, and high-temperature applications. Many of these parts are delicate, have a fragile surface, or are coated with a relatively soft film. While hard metal parts such as those made of stainless steel can be cleaned at the lowest ultrasonic frequencies at around 20 kHz, these frequencies produce high-energy cavitation bubbles in the cleaning solution.

When the cleaning action of the bubbles is too powerful, the bubbles can damage delicate structures and cause pitting in fragile surfaces or films. Higher frequencies produce smaller, less energetic bubbles and more gentle cleaning action. Ultrasonic frequencies in the range of 78 to 160 kHz usually won’t damage high purity ceramic parts, but frequencies as high as 430 kHz may sometime be needed to avoid damaging parts for some cleaning applications. Depending on the parts to be cleaned and the contaminants, choosing the right frequency is critical for safe, effective cleaning.

Properly Configured Ultrasonic Cleaners Can Solve Difficult Cleaning Tasks

High purity ceramic parts can be difficult to clean even when the right frequency is used. Sometimes ultrasonic cleaning will result in rough or discolored surfaces, and microscopic structures, smaller than one millimeter, may not be cleaned completely. When used in semiconductor manufacturing, ultrasonic cleaning has to remove submicron particles from surfaces. In medical applications, devices may need to be sterilized as well as cleaned. Not all ultrasonic cleaners can be configured to solve these problems.

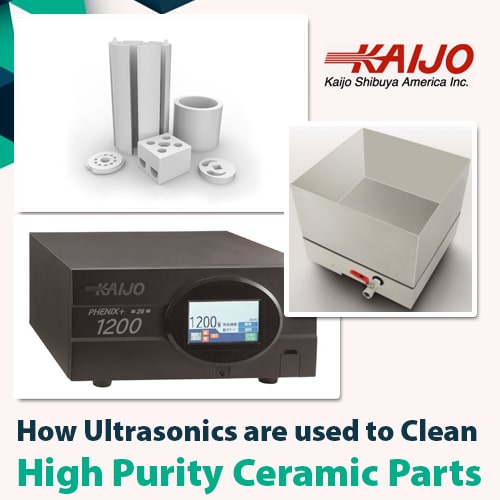

Kaijo’s ultrasonic cleaners can handle the most difficult cleaning applications. Systems such as the Phenix+ and the Phenix Hyper can provide the required power levels of up to 1200 W and deliver the most effective waveform. The Phenix+ industrial ultrasonic generator provides programmable frequency modulation that can be configured to enhance the specific cleaning application. Also, Kaijo’s Water Resonance System (WRS) can condition the water to provide three-dimensional cleaning and increased cleaning power. Cleaning tank materials, cleaning solution temperature, and the addition of solvents or disinfectants to the cleaning solution can also play a role in effective cleaning performance. Configuring the ultrasonic cleaner to include the features and functions required for a specific application is important for obtaining the required cleaning results.

Kaijo Can Help Configure Ultrasonic Cleaning Systems for Specialized Cleaning

Kaijo has the experience and in-house expertise to recommend ultrasonic cleaning systems with the right configurations and frequencies needed to clean specific high purity ceramic parts. The company can make sure the systems will deliver effective cleaning, even for difficult cleaning applications such as semiconductor part cleaning or medical instrument sterilization.

Kaijo works closely with industrial manufacturers that use high purity ceramic parts at their facilities and is familiar with their unique cleaning requirements. In addition to providing standard ultrasonic cleaners from their complete line of ultrasonic products, Kaijo can also customize equipment and integrate special cleaning functions to meet difficult cleaning applications that include cleaning high purity ceramic parts. Contact Kaijo for a free consultation to discuss the details of your cleaning application requirements.