Maximizing Ultrasonic Cleaning Performance with Kaijo’s WRS Technology

May 7, 2024

Ultrasonic cleaning stands out as a critical technology in industrial manufacturing, known for its precision and ability to clean complex components effectively. As industries search for ways to increase cleaning efficiency, the introduction of cutting-edge solutions becomes essential. Kaijo’s Water Resonance System (WRS) represents a key breakthrough, specifically engineered to optimize industrial ultrasonic cleaning processes.

Ultrasonic cleaning stands out as a critical technology in industrial manufacturing, known for its precision and ability to clean complex components effectively. As industries search for ways to increase cleaning efficiency, the introduction of cutting-edge solutions becomes essential. Kaijo’s Water Resonance System (WRS) represents a key breakthrough, specifically engineered to optimize industrial ultrasonic cleaning processes.

This innovative technology addresses some of the common challenges with using industrial ultrasonic cleaners, including consistent efficiency, enhanced uniformity, and reduced energy use—key concerns for improving productivity and operational sustainability within modern manufacturing environments. This article discusses the revolutionary impact of Kaijo’s WRS on ultrasonic cleaning operations, to discover its role in improving efficiency and providing consistent results across applications.

Understanding Ultrasonic Cleaning and Its Challenges

Ultrasonic cleaning is a sophisticated process that uses high-frequency sound waves to remove dirt, grease, and other contaminants from various items. The goal is precision cleaning. This technology has widespread application in numerous sectors, such as automotive, electronics, healthcare, where the cleanliness of component has an enormous effect on product quality and functionality.

Ultrasonic cleaning relies on the generation of sound waves to produce microscopic bubbles in a cleaning solution, known as cavitation. Once formed, these microscopic bubbles implode with great force, dislodging contaminants from surfaces, even in the most difficult-to-reach areas of items being cleaned.

Although traditional ultrasonic cleaning systems may seem effective, process engineers and industrial professionals often face several difficulties when using them:

- Efficiency: Ensuring that the cleaning process is time-efficient while maintaining high-quality results is a balancing act that many find challenging.

- Uniformity: Maintaining consistent cleaning across all parts of complex components can be challenging, especially with different shapes and materials.

- Energy Use: With rising energy costs and greater awareness about environmental concerns, optimizing energy consumption while maintaining effective cleaning is becoming increasingly critical.

These challenges often necessitate frequent adjustments and monitoring, leading to inefficiencies and increasing operational costs. As industries evolve and require more from their cleaning processes, improved technologies like Kaijo’s Water Resonance System (WRS) become ever more apparent, providing solutions that meet and even surpass rigorous industrial application standards.

The Role of Kaijo’s WRS in Ultrasonic Cleaning

Kaijo’s Water Resonance System (WRS) technology is a significant advancement to traditional ultrasonic cleaning systems, designed to address challenges related to efficiency, uniformity and energy consumption. The WRS technology works by optimizing the distribution of ultrasonic energy throughout the cleaning bath for more even and intensive cleaning action.

How WRS Technology Amplifies Ultrasonic Cleaning:

- Increased Cavitation Energy: WRS technology helps increase the generation of cavitation bubbles for an accelerated cleaning process. By increasing the density and uniformity of bubbles throughout the solution, WRS ensures that every part of the submerged items receives equal cleaning attention, which enhances the overall cleaning effectiveness.

- Uniform Distribution of Ultrasonic Waves: One of the hallmarks of the WRS system is its ability to evenly distribute ultrasonic waves across its cleaning bath. This uniform distribution helps eliminate dead zones (areas with insufficient cavitation) that often characterize traditional setups and cause inconsistent cleaning results.

- Energy Efficiency: WRS technology improves cleaning efficiency and reduces energy consumption. Optimizing ultrasonic energy use allows for lower power settings with comparable or better cleaning outcomes, supporting sustainability initiatives within industrial operations.

Kaijo’s WRS stands out as an invaluable tool in ultrasonic cleaning operations, particularly those requiring precision and reliability. By eliminating inefficiencies found with traditional systems, the WRS provides a cost-effective and performance-boosting alternative to improve overall ultrasonic cleaning results.

Enhancing Process Efficiency with WRS

Kaijo’s Water Resonance System (WRS) was specifically designed to meet the stringent demands of ultrasonic cleaning in industrial settings, providing a remarkable increase in efficiency. This claim can be verified with both visual and quantitative evidence.

Quantitative Data Show Improvements

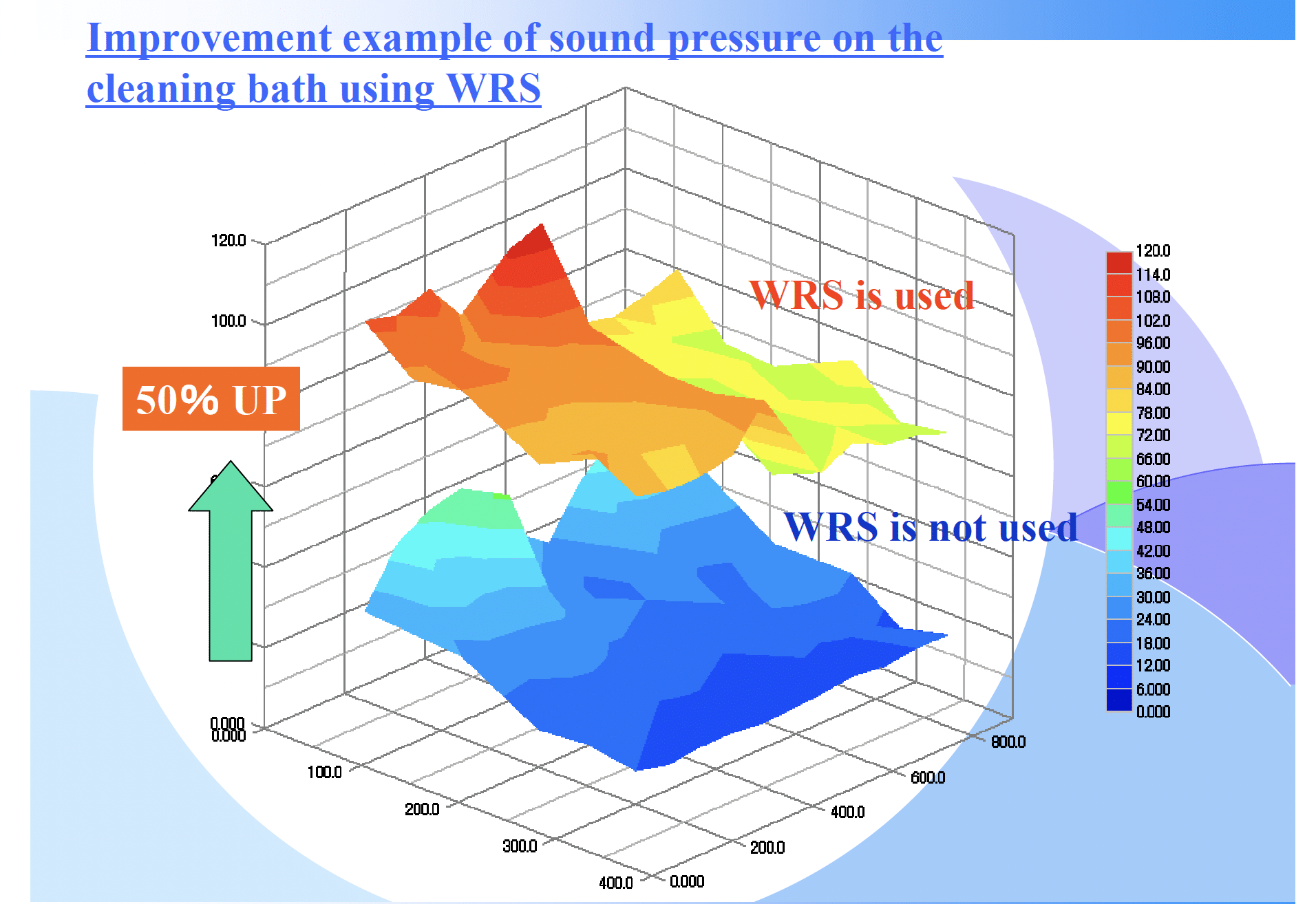

According to recent studies, WRS technology has produced remarkable enhancements in ultrasonic cleaning performance. The graph below illustrates a remarkable 50% increase in sound pressure within the cleaning bath when WRS is utilized versus traditional systems without WRS. This substantial increase in sound pressure correlates directly with more effective cavitation processes and, thus, more efficient cleaning operations.

Visual Evidence of Improved Cleaning Capabilities

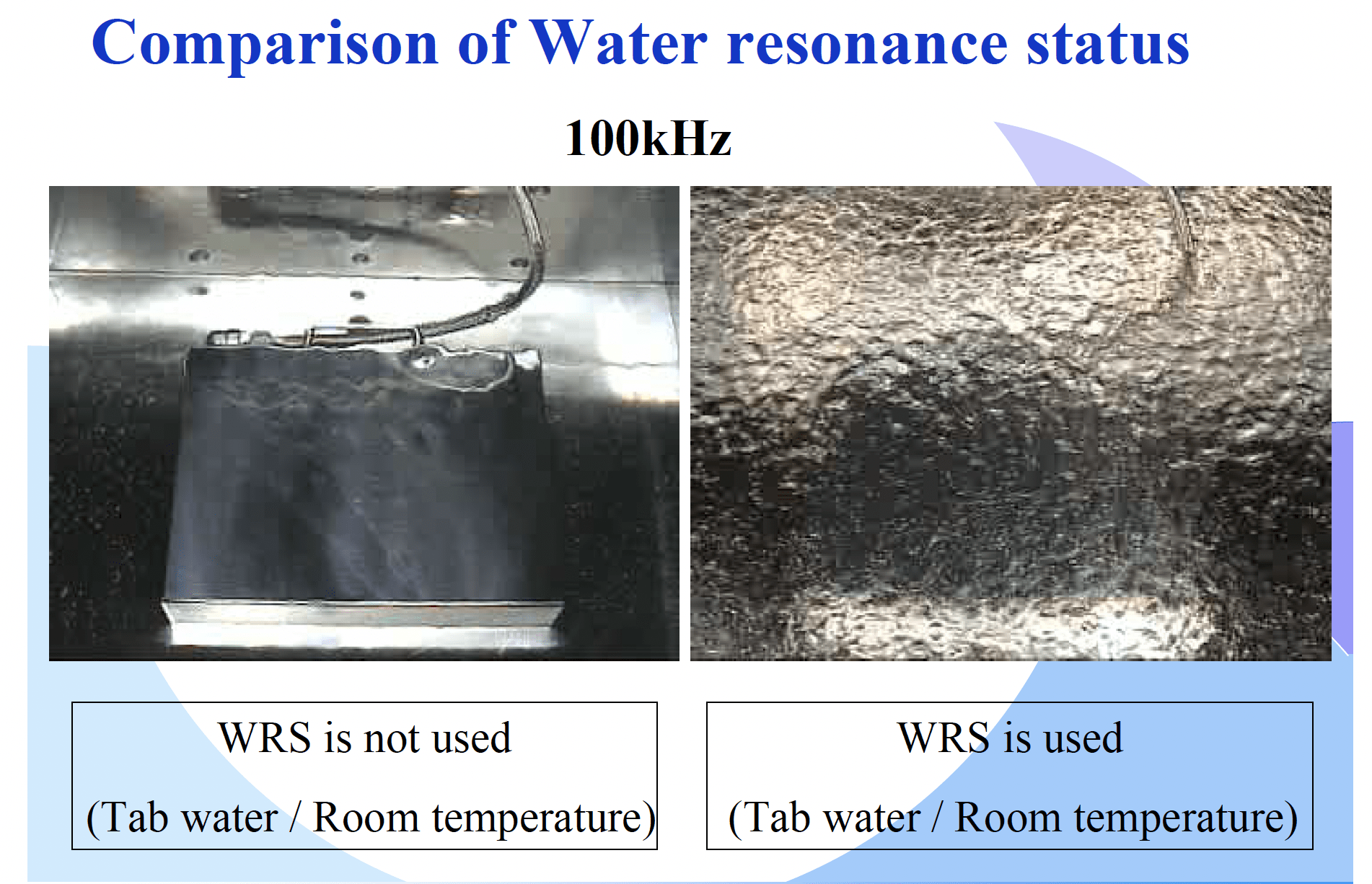

Accompanying this data is a visual comparison that offers an intriguing before-and-after snapshot of ultrasonic cleaning with and without WRS. The left side of the photo below, without WRS, shows a relatively less active cleaning bath. In contrast, the right side of the image, which depicts the use of WRS, shows a dynamic and turbulent cleaning action, indicative of the enhanced cavitation energy that the WRS system brings to the table.

WRS facilitates deep cleaning action that stands out visually; items processed through its system demonstrate noticeable differences in cleanliness. Surfaces emerge free of residue typically left behind by less efficient systems, demonstrating its uniformity and thoroughness of cleaning.

WRS technology adds significant value to ultrasonic cleaning processes. By increasing power output while simultaneously cutting energy consumption, Kaijo’s WRS stands out as an innovative solution for process engineers looking to enhance operational efficiency and productivity. Industry professionals can now see firsthand how WRS’s ultrasonic cleaning can transform into real-world benefits that translate directly to increased, cost-effective, and eco-friendly cleaning procedures.

Achieving Uniform Cleaning with Advanced Technology

Uniformity is the benchmark of excellence when it comes to industrial ultrasonic cleaners, with every part being meticulously cleansed regardless of its complexity. Traditional ultrasonic systems often struggle with inconsistent results due to large bubbles that disrupt the propagation of ultrasonic waves. These disruptions can result in uneven cleaning, with certain areas receiving less cavitation, which produces less-than-ideal results.

Overcoming Disruption with WRS

Kaijo’s Water Resonance System (WRS) overcomes this challenge by ensuring the formation of smaller, uniform bubbles that do not interfere with the ultrasonic wave paths. The innovation lies in the WRS’s ability to create an environment where these smaller bubbles proliferate uniformly throughout the cleaning bath, thus preventing the large bubble disruptions typical in conventional systems. By aligning the bubbles in a uniform pattern, WRS facilitates the consistent progression of ultrasonic waves throughout the bath, which is crucial for achieving an evenly cleaned surface.

Enhanced Cavitation for Uniform Results

The graphic illustration contrasts the traditional scenario with the WRS-enabled environment. On the left, larger bubbles scatter the ultrasonic waves, creating areas of low cavitation—essentially, blind spots in the cleaning process. On the right, with WRS, we see a well-ordered array of smaller bubbles that complement the wave propagation, ensuring that the entire liquid medium resonates with the ultrasonic energy. This orchestrated process of cavitation results in a powerful, uniform cleaning action.

The impact of this enhanced cavitation is not just theoretical; it translates into tangible benefits for industrial cleaning processes. With WRS technology, ultrasonic cleaners are no longer just a tool but a reliable solution that guarantees consistent and high-quality results across all parts. This reliability is crucial in industries where the margin for error is non-existent and the cost of inconsistency can be high.

By integrating WRS into ultrasonic cleaning systems, Kaijo has addressed one of the most persistent challenges in the field: delivering uniform cleaning efficiency at a microscopic level. This advancement paves the way for industries to not only achieve but also to maintain the highest standards of cleanliness, with greater control over their cleaning outcomes and operational costs.

Considering Kaijo’s Solutions for Your Industrial Needs

Kaijo’s Water Resonance System (WRS) stands out as an equipment choice that not only meets the various industrial cleaning needs but also offers significant improvements over traditional cleaning methods.

Integrating WRS with Existing Systems

Kaijo’s WRS is not a standalone solution; rather, its real value lies in its versatility and compatibility with existing ultrasonic cleaning systems. This provides a seamless integration that enhances the performance of current equipment without the need for a complete system overhaul. Furthermore, the WRS can easily adapt to diverse industrial settings by accommodating various sizes and configurations of ultrasonic cleaning tanks.

Broadening Industrial Cleaning Capabilities

The adoption of WRS technology in an industrial cleaning setup broadens the capabilities of the cleaning process. By addressing common challenges associated with uniform cleaning results and energy usage, the WRS provides industries with a competitive edge. With these advancements, companies can improve product quality and consistency and reduce operational costs.

The Versatility of Kaijo’s WRS

Kaijo’s WRS offers incredible versatility due to its ability to accommodate varying ultrasonic frequencies and cleaning solutions, making it suitable for a range of cleaning applications. These include delicate electronics that require precision cleaning and industrial components that need intensive decontamination—the WRS adjusts to meet these varying requirements with precision.

Kaijo provides innovative ultrasonic cleaning solutions that meet market demands for greater sustainability, providing more than just products – but a partnership in attaining industrial cleaning excellence. By understanding and meeting specific challenges faced during ultrasonic cleaning processes, Kaijo demonstrates its dedication to innovation and customer satisfaction.

Elevating Standards with Kaijo’s WRS

Kaijo’s Water Resonance System (WRS) optimizes the efficiency of ultrasonic cleaning technology. Its ability to deliver uniform and efficient cleaning power while integrating easily with existing systems makes it an indispensable tool for industries demanding the highest quality standards. The WRS represents Kaijo’s commitment to innovation and to the success of their customers. For those in the industrial sector looking to revamp their cleaning processes and embrace efficiency, Kaijo’s WRS provides a clear way forward. Explore the transformative benefits of WRS technology further and consider how it can make a significant difference in your operations. Contact Kaijo for a free consultation and take the first step towards optimizing the performance of using industrial ultrasonic cleaners for your application.